BMW Manufacturing employs more than 11,000 people at its eight million square-foot campus. The Spartanburg plant assembles the BMW X3, X4, X5, X6, X7, and XM Sports Activity Vehicles and Coupes and their variants. Since 1994, our associates have been proud to assemble more than seven million safe, premium-quality BMWs for our customers around the world. According to the U.S. Department of Commerce, the BMW Group is one of the largest automotive exporters by value from the U.S. with a total export value of about $10.1 Billion in 2024.

Facts & Figures.

Models assembled.

The Spartanburg plant assembles the BMW X3, X4, X5, X6, X7, and XM Sports Activity Vehicles and Coupes and their variants. More than 1500 vehicles are assembled daily and exported to 120 countries.

- BMW X3

- BMW X4

- BMW X5

- BMW X6

- BMW X7

- BMW XM

BMW Manufacturing.

BMW Manufacturing employs more than 11,000 people at its eight million square-foot campus. The Spartanburg plant assembles the BMW X3, X4, X5, X6, X7, and XM Sports Activity Vehicles and Coupes and their variants. Since 1994, our associates have been proud to assemble more than seven million safe, premium-quality BMWs for our customers around the world. According to the U.S. Department of Commerce, the BMW Group is one of the largest automotive exporters by value from the U.S. with a total export value of about $10.1 Billion in 2024.

The primary technologies involved in the entire process are three body shops, two paint shops, two assembly halls, and several logistics centers. The Spartanburg plant assembles more than 1,500 vehicles per day, running on two shifts. More than 50 percent of its vehicles are exported to 120 countries around the world. Many of our completed vehicles are loaded onto rail cars at the plant; then, a train transports them to the port in Charleston, South Carolina, or other southern ports, where they are shipped to Europe, China and other global destinations. BMWs for the U.S. market are loaded onto auto transport carriers at the plant.

Body Shop.

The body shop is where a brand new BMW begins to take shape. Due to the sophisticated design, the intricate processing as well as the high and ultra-high strength steels used, BMW car bodies are among the safest in the global automotive industry. In the plant’s new 1.2 million square foot shop for all models, more than 2,000 high-tech precision robots carry out the highly complex assembly tasks. Each vehicle spends 6 hours in the body shop. 1,000 team members assemble 1,450 car bodies a day.

The body begins as 400 pieces of steel that are welded together and 99 percent of the welding is automated. Using advanced welding technology, there are about 6,000 welds spots per vehicle with approximately 400 rivet and studs per vehicle. Associates constantly monitor the quality of welding points and ensure the car bodies’ dimensional accuracy and perfect surface quality. Spartanburg was the first plant in the BMW Group network to fully implement Best Fit technology for hang-on parts, where accuracy is within tenths of a millimeter.

Paint Shop.

BMW Manufacturing’s highly- innovative and eco-friendly paint shop comprises of two halls, Paint Shop North and Paint Shop South totaling ~145,000 m² (1,560,767 ft2). It is here where car bodies are painted to a flawless finish, not only assembling an impressive appearance but maximum corrosion protection. The shop has more than 240 highly efficient robots working together with paint shop associates who monitor the car through every stage of the process. This provides BMW maximum flexibility in terms of responding to customers’ special wishes for specific colors or matte paints.

Using environmentally friendly processes, such as the use of water-based paint coats, and state-of-the-art application processes, the BMW body receives 5 coats of paint. Each vehicle receives two protective corrosion coats, sealant, basecoat 1, basecoat 2, and then clear coat. In addition, every BMW also receives supplemental bead seams of sealer for sound deadening, and cavity wax that adds further rust protection. The entire process takes 12 hours, with the vehicle traveling around 4 miles and adding 20 pounds of weight to the body. This is a thickness of 120 microns, which is the equivalent to the width of 5 human hairs.

At BMW we are always seeking to set new standards, in particular when it comes to resource conservation, sustainability and environmental protection. The paint shop’s Integrated Paint Process (IPP) established in 2010, is a more efficient method. It combines the latest in robot application equipment, as well as a new ventilation technology which yielded an ultra-high-performance paint shop that (in 2010) reduced the plant’s energy consumption by 30%. It also reduces the total amount of process time per vehicle by 80 minutes. This is a 40% increase in productivity.

Another example, is the paint shop's installation of the high pressure reverse osmosis unit. This unit allows waste-water from the assembly processes, which would normally be pretreated and discharged to sewer, to be filtered and reused within the assembly process. In 2017, this process reduced BMW Plant Spartanburg’s water consumption by 26.8 million gallons.

Assembly.

BMW Manufacturing has two assembly halls . The X5, X6, X7 and XM models are transported from the paint shop to the assembly hall via a stacker. The X3 and X4 models travel a quarter of a mile, taking nearly 40 minutes, on a conveyor to the plant’s second assembly facility. The conveyer holds 130 bodies at one time.

Doors are one of the most complex parts of the vehicle to assemble, being made up of 96 working parts including the power locks and power windows. Even with so much complexity, there is flexibility. In the door line, for example, BMW uses a “kitting solution” enabling associates to pick certain parts used in the vehicle’s doors, and putting them together into a kit that then travels down the line with the vehicle. The assembly department also uses Poka Yoke methods, such as color coding, Pick-to-Light and light curtains to manage such part complexity. The plant has the flexibility to change a customer’s order six days prior to the scheduled assembly.

Due to the large number of variants, BMW ensures a safe process by assembling components for instrument panel, front end, doors and powertrain in a separate assembly area. These modules are then delivered at the right time and in the right order – just in sequence – to the main line where they are positioned in the vehicle. The assembly shop’s high ergonomic standards provide associates with added comfort to complete each process, some examples are Raku chairs, the tilted carrier position and exoskeleton vests. A true highlight of the assembly process is the fully-automated fitting of the engine, transmission and chassis to the vehicle body- also known as engine marriage. The powertrain is individually fitted to the vehicle, nearly completing the BMW assembly process.

The vehicles assembled at Plant Spartanburg are made for customers around the world. Each vehicle is uniquely assembled to customer or dealer specifications. BMW offers customers so many multiple variants and trim options, that the plant could assemble vehicles for six months straight without assembling a duplicate vehicle.

Logistics.

At BMW, it takes a strong logistics team to orchestrate a complex operation, bringing together the 20,000 fine detailed parts needed to assemble each vehicle. There are over 600 suppliers delivering parts to BMW from all around the world. Approximately 1300 truckloads, 2 air freight deliveries and 60 sea containers bringing around 7 million parts to the Spartanburg plant daily. Innovative assembly technologies and experienced associates ensure that these parts result in a premium quality product.

Logistics uses Hydrogen fuel cell powered material handlers to delivery 70 percent of the parts to the line. This is a sustainable means of transportation, the only emissions are water vapor and heat. The fleet at BMW Manufacturing is one of the World’s Largest Hydrogen Fuel Cell Fleet for a single site, delivering parts on time and in sequence directly to the line.

Using a robust IT landscape ensures on-time sequence, warehouse and direct deliveries. Sophisticated weather and parts tracking systems are used for transparency of parts locations and delivery timing. Geofencing, set to a specific radius range around the plant, is also used to identify real-time parts location.

BMW Manufacturing is equipped to meet the demands of a complex vehicle assembly process with advanced innovations such as the vision guided vehicle (VGV). The VGV is an efficient, reliable, and safe automated tugger/forklift that is vision controlled with no person onboard. It uses both cameras and laser to travel along a programmed route. Using autonomous vehicles saves nearly 500 meters per round trip.

Battery Assembly.

Plant Spartanburg is an integral part of BMW Group’s strategic electro-mobility initiative and has been assembling high-voltage batteries on site since 2015. As a pioneer for electro-mobility in the U.S., the Spartanburg plant assembled the first series plug-in hybrid vehicle, the BMW X5 xDrive40e, from 2015-2018. The plant’s battery assembly team assembled a total of more than 45,000 batteries during those four years (2015-2018).

The Spartanburg plant also has its own battery assembly facitliy onsite which assembles lithium-ion battery modules for three plug-in hybrid electric vehicle (PHEV) models: the BMW X3 xDrive30e, the BMW X5 xDrive50e, and the BMW XM. In 2023, 77,388 "electrified" BMWs were assembled.

Plant Tours & Zentrum Museum.

Experience the past, present and future of BMW in the only BMW museum in North America or see for yourself how the Ultimate Driving Machine is assembled during a guided plant tour.

Charity Golf.

Careers at

BMW Group Plant Spartanburg.

Are you interested in working at BMW Group Plant Spartanburg?

Request Accomodations.

Equal Employment Opportunity.

BMW Manufacturing values diverse talent and will continue to be an equal opportunity employer.

BMW Manufacturing provides equal opportunity to all qualified applicants and associates for competitive employment openings and will receive consideration for employment without regard to race, color, religion, sex, sexual orientation, gender identiy, national origin, disabilty or protected veteran status.

News from BMW Group Plant Spartanburg.

BMW Manufacturing Celebrates Award-Winning Vehicles As It Continues To Build A Sustainable Future.

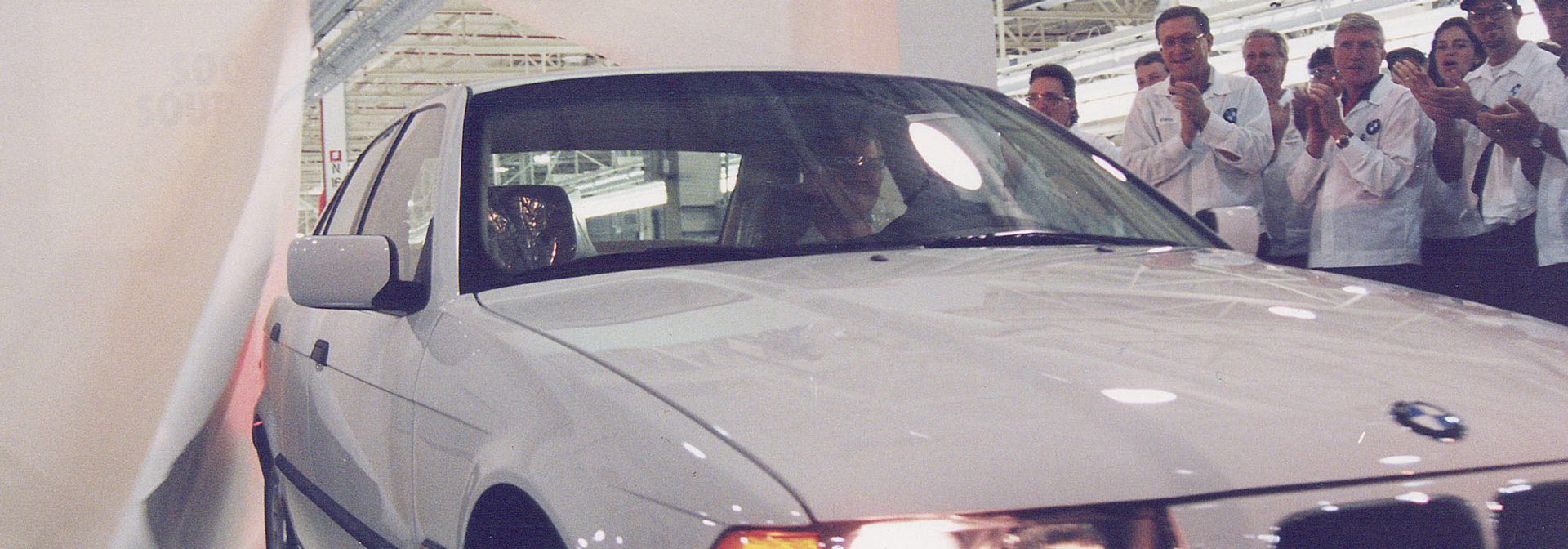

BMW Manufacturing Celebrates Seven Million BMWs Assembled in the United States.

BMW Manufacturing Continues as the Largest Automotive Exporter by Value in the U.S.

For the latest from BMW Group Plant Spartanburg and a host of other news, check out the BMW Group PressClub.

Our History.

Our Responsibility.

BMW is committed to being a responsible, sustainable, and innovative partner for communities worldwide. Corporate sustainability is embedded in every aspect of our operations—from clean processes to green recycling practices—yet our reach extends beyond the plant footprint. We take responsibility for cultural and social issues as well, supporting educational programs and diversity initiatives across South Carolina.

Being a good corporate citizen is central to who we are. We believe in being a strong economic partner by investing not only in business, but in people—through support for community organizations and extensive workforce development programs. We are convinced that a robust responsibility policy is essential for the well-being of future generations. That is why we focus on corporate sustainability, social responsibility, and positive economic impact.

Contact & Directions.

BMW Manufacturing and the BMW Performance Center are located within close proximity to the Greenville Spartanburg International Airport, Charlotte Douglas International Airport and Interstate 85.

1400 Highway 101 S

Greer, SC 29651

1400 Highway 101 S

Greer, SC 29651

Visitors Parking.

Visitors parking is located beside the Zentrum Museum. Please follow the signs. Plant visitors should proceed to the security booth near the turnstiles. Security will help direct you to the Visitors Lobby. Once in the lobby, you will need to provide the receptionist with your name and the person you are meeting. The receptionist will contact the appropriate contact.

(888) 345-4269

1155 Highway 101 S

Greer, SC 29651

VOE number is (864) 802-7333.

Head of Corporate Communications