Our heart beats Bavarian: The over 100-year history of Bayerische Motoren Werke and the region is firmly rooted in one another. For example, there is no question that we will assume responsibility for the approximately 30,000 jobs at the BMW Group in Eastern Bavaria in order to secure prosperity and continue to share our success with the region in the future.

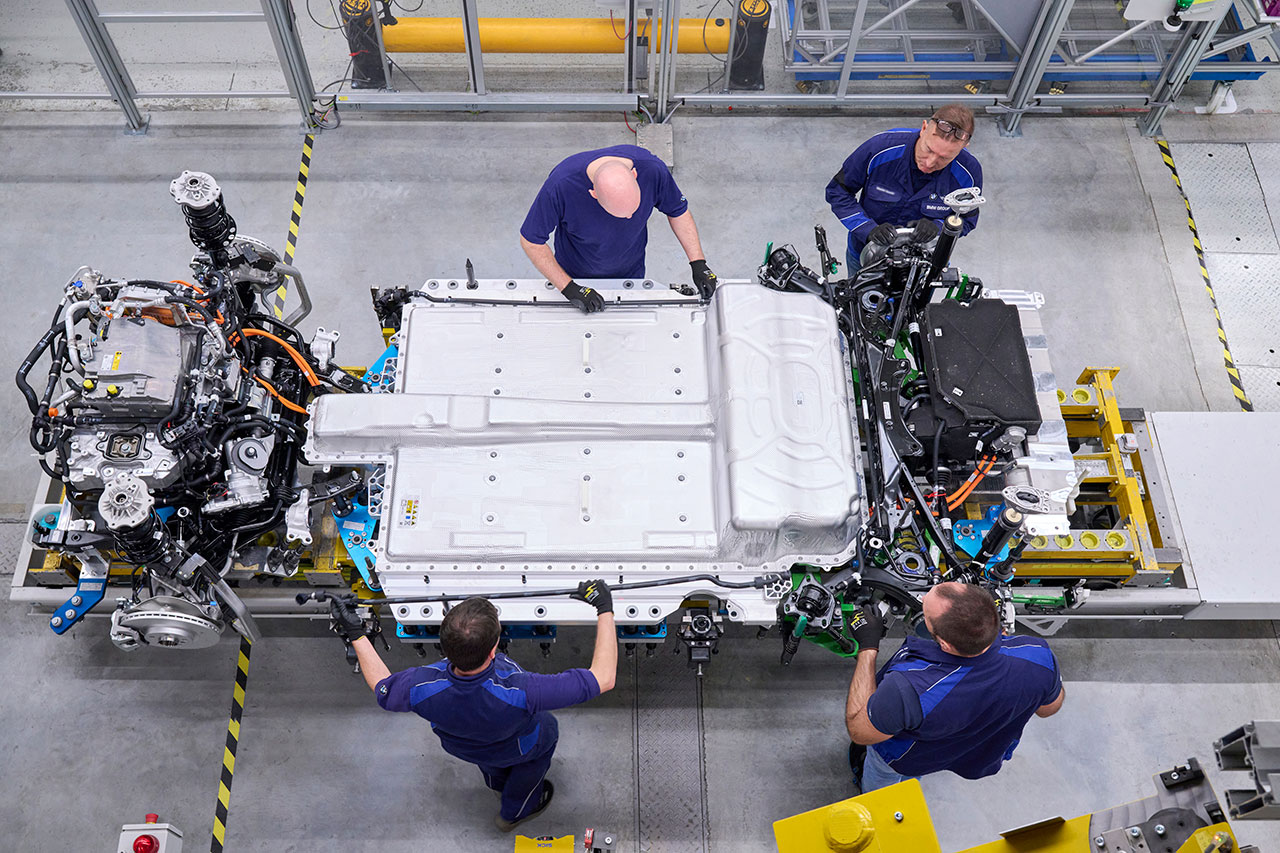

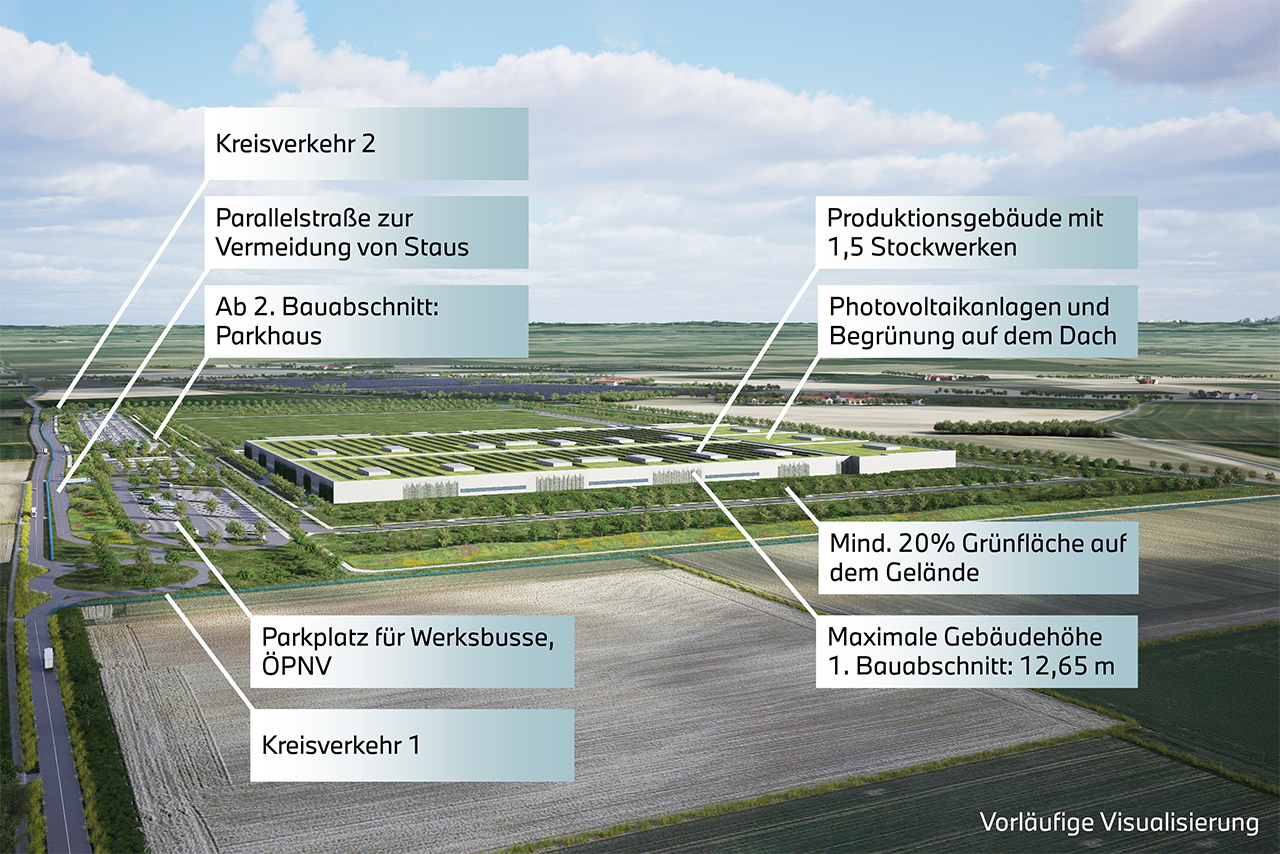

Our heart beats strongly for electricity: We are consistently focusing our company on electric mobility and thus making it future-proof. An essential component of electric vehicles is the high-voltage battery, which supplies the electric drive with power. To this end, we are planning to build a new location in Irlbach and Strasskirchen in Lower Bavaria. From here, the BMW plants in Dingolfing, Regensburg and Munich are supplied with high-voltage batteries within short distances. In this way, we secure our current and future jobs and those of our Bavarian partners and suppliers in the long term.

Electric drives are a prerequisite for climate-neutral mobility in the future. That is why the BMW Group is already consistently expanding its range of electric vehicles and offers all-electric cars in virtually all market segments. With the Neue Klasse, the BMW Group is starting a new era of mobility in 2025 and wants to achieve that more than half of its global vehicle sales are fully electric before 2030.

The BMW Group is clearly committed to the Paris Climate Agreement. With our all-electric vehicles, we are making a decisive contribution to achieving the ambitious CO₂ reduction goals. By 2050 at the latest, we want to achieve “net zero” in terms of our CO₂ emissions across the entire value chain.