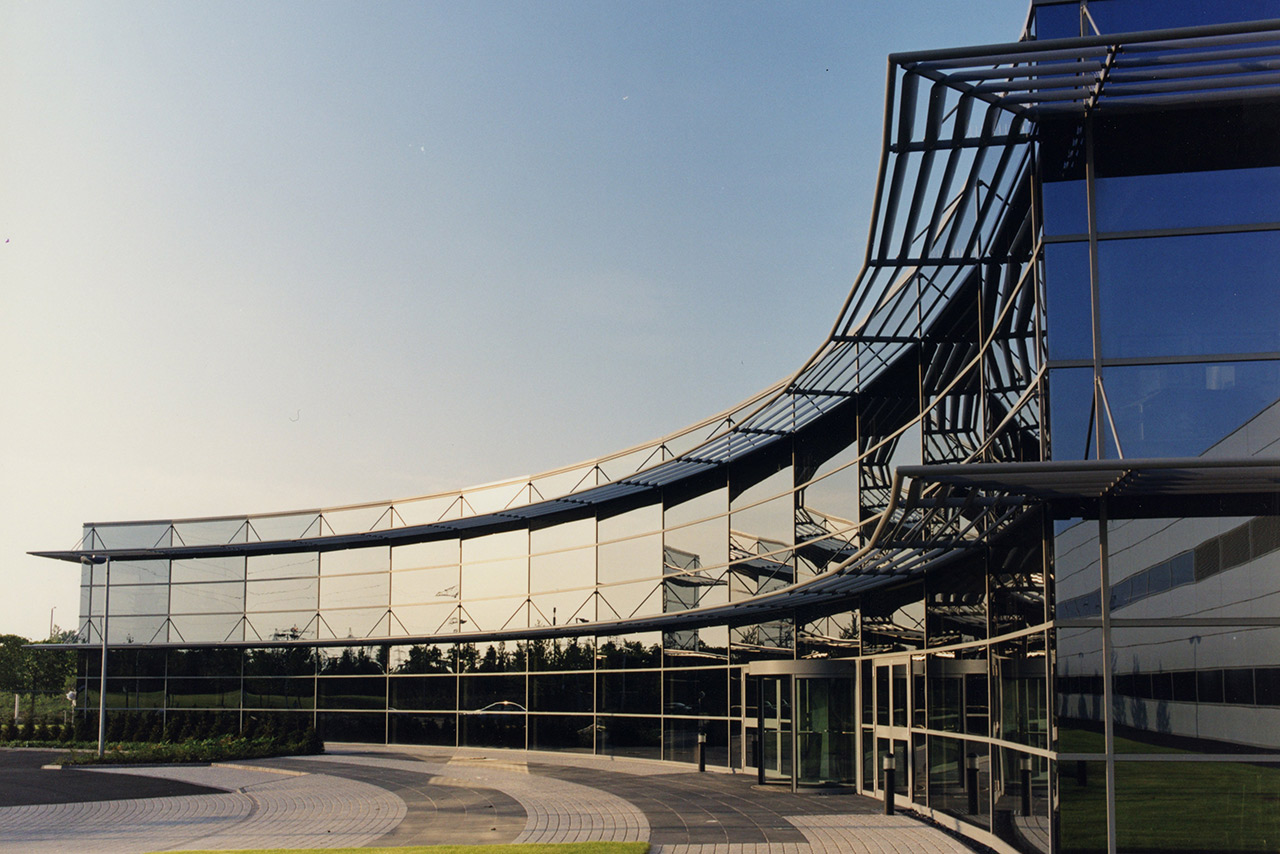

Plant Hams Hall is a cutting-edge production facility located in North Warwickshire, not far from Birmingham, in the UK. It’s a part of the company’s global drivetrain division, committed to supporting BMW Group’s open technology approach to efficient mobility.

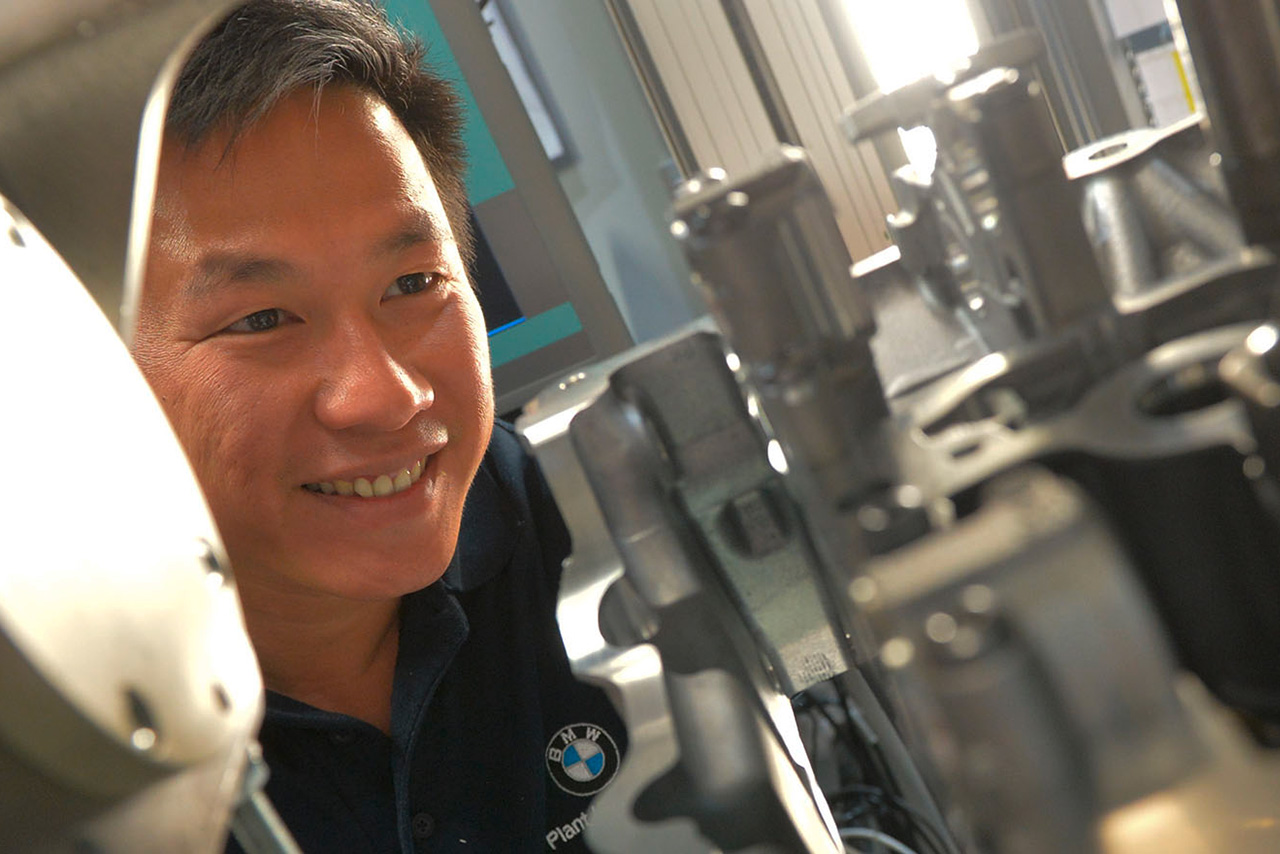

From producing the latest generation of engines and machining key engine components, to starting a journey towards new technologies, Plant Hams Hall is a high performing plant supplying engines for many of the latest products, powering MINI, BMW and Rolls-Royce Motor Cars.

Since first opening in 2001, the plant has delivered both high-volume production as well as low-volume flexible manufacturing and special projects, making a long-term and valuable contribution to the success of BMW Group.