BMW Group Plant Leipzig is one of the world’s most cutting-edge car plants. Series production launched in March 2005, and we now make about 1,300 cars a day. We currently manufacture the BMW 1 Series, BMW 2 Series Gran Coupe, BMW 2 Series Active Tourer and MINI Countryman. The BMW Group has so far invested more than €5 billion in our Leipzig site, and we now have a permanent workforce of some 6,800 employees. Car production at Leipzig is carried out in four stages – in the press shop, bodyshop, paintshop and final assembly. BMW Group Plant Leipzig also makes painted plastic components and high-voltage batteries.

Facts & figures.

Models produced.

BMW Group Plant Leipzig makes the BMW 1 Series, BMW 2 Series Gran Coupe, BMW 2 Series Active Tourer and MINI Countryman for export worldwide. Click through the gallery for more on vehicles made in Leipzig:

A car is born.

- Press shop

- Body construction

- Paintshop

- Assembly

High-tech materials perfectly formed.

The press shop supplies the sheet metal parts required to make the body. Production of these parts starts with coils of steel and aluminium that weigh several tonnes each. First, the metal from the coils is fed through the blanking line and cut into blanks. These are then drawn, bent and punched in a multistage process involving fully automated, state-of-the-art high-speed servo presses. The result is formed parts such as side frames, doors, engine bonnets and roofs.

The press shop processes a function-oriented mix of proven deep-drawing steels and high- and higher-strength materials. So, from the moment we start producing these individual parts, we are already laying the foundations for realising the unique designs of our vehicles and their extremely torsion-resistant yet lightweight bodies.

Plant Leipzig’s press shop technology is the most cutting-edge in the world and includes one press capable of generating a total press force of up to 10,000 tonnes.

Precision-made.

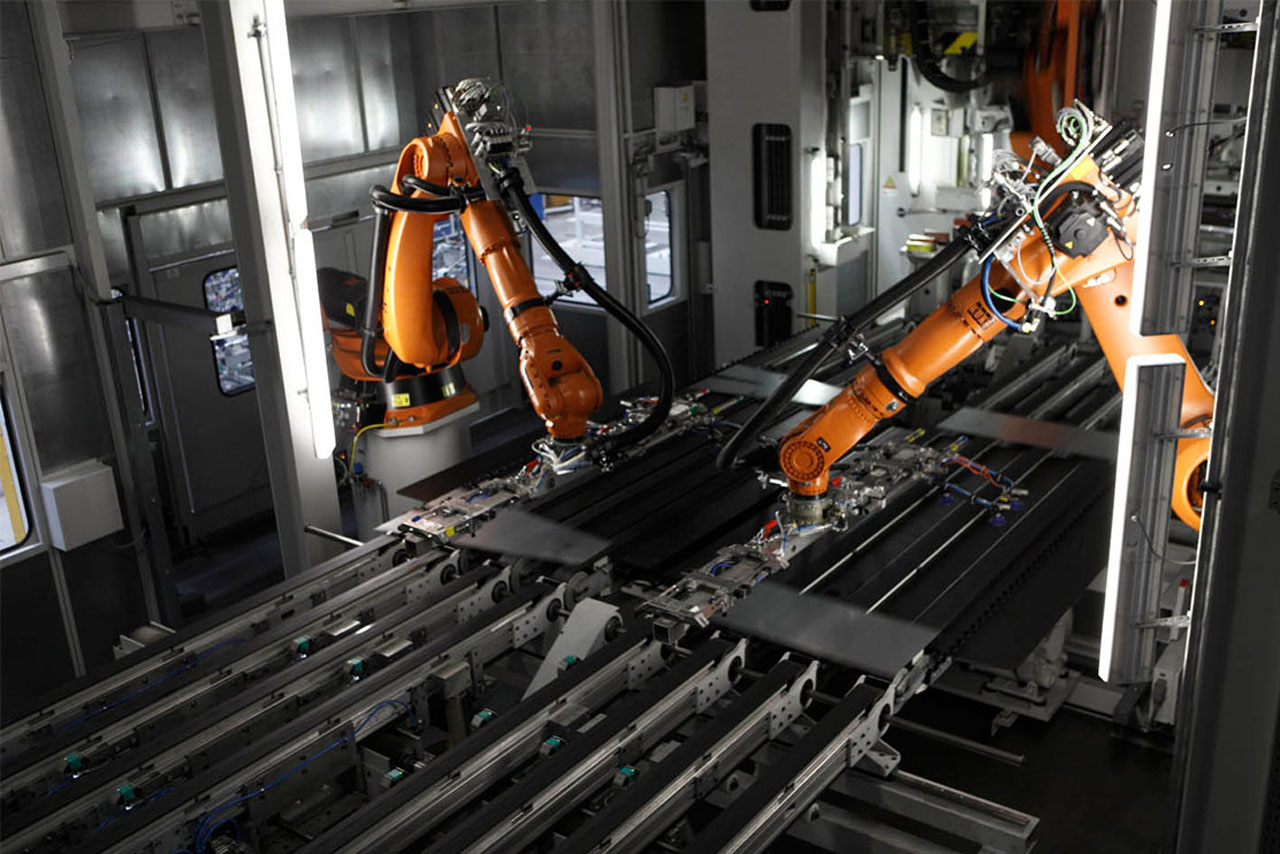

Constructing a car body involves joining several hundred steel and aluminium components of different sizes and thicknesses to produce a high-precision result. The job is done by a team of absolute experts in their field who employ welding and joining technologies – such as spot welding, soldering, bolting, bonding and the latest laser welding techniques – to create bodies that are precise to the millimetre. The physically strenuous and complex work is carried out by robots that work with maximum accuracy and are controlled and maintained by our highly qualified team.

Spot welding is up to 95 percent automated, with robots working on precisely predetermined points of the body. So, the body shop is the most highly automated area of BMW Group production.

Shine and shield.

The colour of a car’s paintwork is probably its single most powerful visual element. But it also protects the vehicle and helps retain its value.

The application process starts by dipping the body in a cleansing and de-greasing solution before coating it in a layer of zinc phosphate, which offers lasting corrosion protection. Then, up to four more coats of paint are applied to protect the body from environmental stressors and give it a rich, lasting colour and radiant finish. Between each coat, rigorous quality inspections are carried out in the paintshop, with lab specialists using environmental simulations to verify the colourfastness and their resilience to environmental influences of the various paints.

Individual and precise.

The finishing touches are added to the painted bodies by our team of highly trained and experienced specialists. Thanks to our Individual programme, we can realise even the most unconventional of customers’ wishes, with different equipment packages, add-ons, country-specific packages and much more besides making for an unmistakable, customised product. The almost unlimited equipment options mean it’s highly unlikely that two identical vehicles in a row will ever leave the assembly line.

In final assembly, the car production process reaches its high-point with what’s known as the “marriage”. This is when the drive – comprising the engine, transmission, axles and exhaust system – is “married” with the corresponding body and bolted into place. By this point the team have carried out thousands of operations, and the vehicle can now stand on its own four wheels. They then fit the final parts and start the engine. After a plethora of tests have been successfully completed, the brand-new vehicle can finally roll off the production line.

Careers at

Plant Leipzig.

BMW Group Plant Leipzig offers an attractive working environment with challenging tasks in different departments and professional teams. Ideal opportunities for personal development and performance-related remuneration are a given.

Plant tours.

Experience innovation.

Discover a production facility that’s truly out of the ordinary – on a BMW iFACTORY tour at BMW Group Plant Leipzig.

Our Basic Tour lasts just over an hour and a half and walks you through some exciting aspects of highly flexible production at BMW Group Plant Leipzig. You will get to see how four different models with three drive options from two brands are manufactured together, on one and the same production line.

If you’re really into the tech, the Extended Tour is probably the option for you. It lasts just over two hours and is your opportunity to see for yourself how sheet steel blanks are transformed into actual body components in the press shop. You will also get to see artificial intelligence at work during painting.

News from BMW Group Plant Leipzig.

BMW Group to deploy humanoid robots in production in Germany for the first time.

Representatives from politics, business and society congratulate BMW Group Plant Leipzig on two decades of series production.

BMW Group Plant Leipzig paves the way for hydrogen pipeline link – a world first in car production.

For all the latest from Plant Leipzig and a host of other topics, visit our PressClub.

Our responsibility.

Corporate responsibility is about more than just business success: we invest in innovative processes and production technologies for a sustainable and successful future too. For more on sustainability, our employees, and our environmental and social responsibility, visit the BMW Group website.

You can download information for the public in accordance with §8a of the Hazardous Incident Ordinance (12th Ordinance on the Implementation of the Federal Immission Control Act, German: 12 12. BImSchV) here:

Our History.

2001 Leipzig is chosen as the location for the new BMW plant. 2002 The ground-breaking ceremony takes place, attended by the then Chancellor Gerhard Schröder and BMW AG Chairman at the time Professor Joachim Milberg.

Contact & Directions.

Werk Leipzig

BMW Allee 1

04349 Leipzig

Werk Leipzig

BMW Allee 1

04349 Leipzig

If you have any questions or comments on BMW Group Plant Leipzig, we’ll be happy to help! Email us at:

If you have any questions about our products, your own vehicle or the technical details of our cars, contact BMW Customer Care.

Head of Corporate and Associate Communication

BMW Group Plants Leipzig, Berlin, Eisenach