At the BMW Group, keeping our employees fit and able to work is a top priority. Our workplaces are suited to the job, and we support people’s efforts to take care of their own health.

Our holistic Health Management offers a variety of activities around diet, exercise, mental health and addiction prevention. Our own in-house gym, campaign days and courses help keep the team fit and enthusiastic.

We also have very high standards in terms of occupational safety, above and beyond what is legally required.

A particular challenge we face at the moment, however, is demographic change. As the average age of the team rises, our health programmes are designed to keep employees fit and able to work right through to retirement.

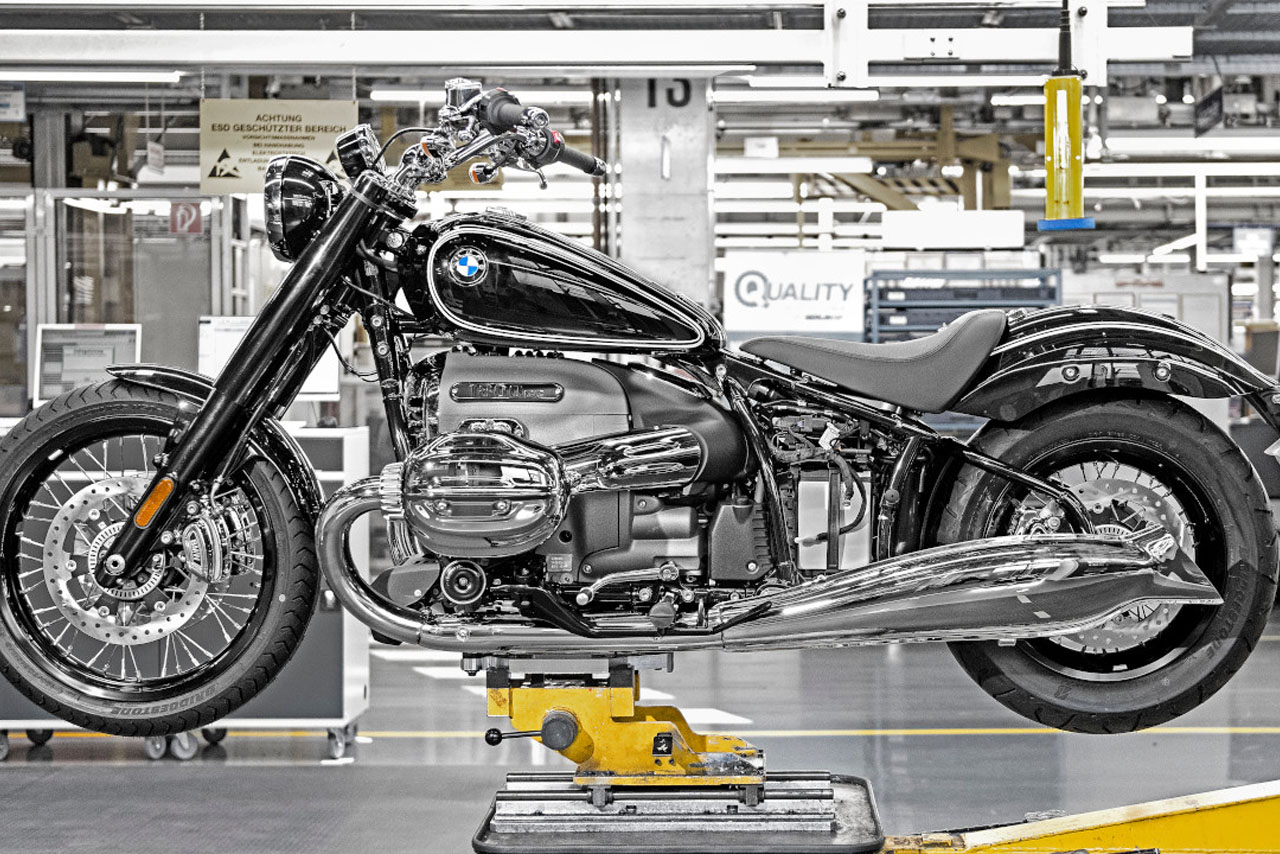

Another issue that’s particularly close to our hearts is talent acquisition and development. Plant Berlin is currently training 120 young people in commercial and technical vocations so that we have the qualified specialists we need to take us into the future.