At BMW Manufacturing, our commitment to environmental responsibility begins inside the plant. As one of the first in the industry to receive the ISO14001 certification we ensure green assembly processes. It starts before assembly begins and does not end until the finished vehicle is shipped to the customer.

Our environmental commitment takes on many forms, such as a solid waste recycling program that reduces the need for landfills, and a water conservation initiative that helps save 9.5 million gallons of water each year. We are constantly looking for new ways to make reductions in energy usage and water consumption, using new alternative energy sources, analyzing our plant processes, and evaluating our environmental impact on the plant property and beyond. BMW is not only concerned with environmental sustainability at the plant, but also in the community. Through corporate sustainability partnerships we proactively support environmental initiatives in the state of South Carolina.

Corporate

Sustainability.

BMW’s environmental concern extends well beyond the plant. By partnering with local organizations we proactively support environmental initiatives in the state of South Carolina. BMW is an annual corporate partner with the Nature Conservancy, who is dedicated to preserving the plants, animals and eco-systems of the Upstate. Together with the Palmetto Conservation Foundation, the BMW Conservation Award was created. This award is given annually to individuals who have made lifetime contributions to protecting South Carolina’s natural, historic and cultural resources. In addition, BMW has teamed with the South Carolina Wildlife Federation (SCWF) in a variety of ways. Ongoing corporate sponsorship of the SCWF helps develop and preserve natural habitats throughout the state. As a member of the Wildlife And Industry Together (W.A.I.T.) program, the BMW facility is serving as a model for on-site conservation.

Another aspect of corporate sustainably is associate engagement. Our associates volunteer annually for the BMW tree planting organized by TreesUpstate. Since the first event in 2014, over 100 trees have been planted at Skyland Elementary and Century Park in Greer, South Carolina. BMW takes on the responsibility for the purchasing, planting and watering of the trees through the first watering season. The trees benefit the local community by the reduction of greenhouse gases and the energy needed for cooling, meanwhile providing an increase in oxygen and habitat for wildlife.

BMW Manufacturing’s original Landfill Gas Project was implemented in 2003 in conjunction with partners Ameresco and Waste Management. Infrastructure was installed at the Palmetto Landfill to collect, clean and compress the methane gas; the gas is then transported through a 9.5 mile pipeline to the BMW plant. The methane gas coming from the landfill is used to more efficiently cogenerate electrical power and heat water, saving BMW several million dollars each year.

In 2009, BMW replaced the original 4 turbines with 2 new highly efficient turbines. The new turbines increased the electrical output from 14% up to nearly 30%. Currently, around 20% of the plant’s total energy requirements are provided by methane gas. The implementation of the landfill gas program reduces CO2 emissions by 9,200 tons per year. This is equivalent to CO2 emissions from 23.5 million miles driven by gasoline-powered vehicles each year.

In February 2012, BMW Manufacturing added new solar panels to provide solar energy to fully power the 24,000 square foot Zentrum Museum and three new electric vehicle charging stations (available for public use). The 400 solar modules, each capable of producing 240 watts of energy, save approximately 135,000 kilowatt hours per year. BMW invested $500,000 in this installation. The benefits of solar energy installation include the addition of an energy program that is self-sustained by renewable energy, further diversifies the plant’s energy platform by harnessing another energy source, and deepens BMW’s overall commitment to sustainability.

In October 2010, the plant announced the implementation of a hydrogen fuel cell fleet of material handling equipment in the plant’s X3 assembly hall. The fleet has since been expanded to all parts of the Spartanburg facility with more than 800 pieces of equipment, making it one of the largest hydrogen fuel-cell fleet in the world on a single site.

In the paint shop, the plant’s Integrated Paint Process (IPP) technology integrates the primer coat process into the top coat process eliminating three process steps: primer, primer over and primer finish. Established in 2010, this more efficient method combined with the latest in robot application equipment, as well as a new ventilation technology yielded an ultra-high-performance paint shop that (in 2010) reduced the plant’s energy consumption by 30%. It also reduces the total amount of process time per vehicle by 80 minutes (This is a 40% increase in productivity).

BMW Plant Spartanburg is committed to the protection of wildlife that call the plant site home. This commitment was strengthened in 2016 with the completion of a site wide biodiversity study. This study was conducted over a one-year period and led to the identification and better understanding of the wildlife living at, or migrating through, the site. Upon completion of the study, BMW Plant Spartanburg implemented some improvements with its wildlife neighbors in mind. One example is the installation of duck nesting boxes at the onsite storm water retention pond. These duck nesting boxes were purchased from the South Carolina Wildlife Federation and provide safe nesting locations for the duck population.

The BMW Group is committed to creating sustainable mobility – from suppliers, to assembly, to the end of the vehicle lifecycle. Every BMW “X” model assembled at Plant Spartanburg not only represents premium quality, but also sustainability in action. BMW Group aspires to be the most successful and sustainable premium assembler for individual mobility.

At BMW Plant Spartanburg, one way we show our commitment to sustainability is our continued efforts to decrease plantwide water consumption. One water conservation project within the facility was the installation of a high pressure reverse osmosis unit in the Paint Shop. This unit allows wastewater from the paint processes, which would normally be pretreated and discharged to the sewer, to be filtered and reused within the paint process. In 2023, this process reduced BMW Plant Spartanburg’s water consumption by 15.9 million gallons.

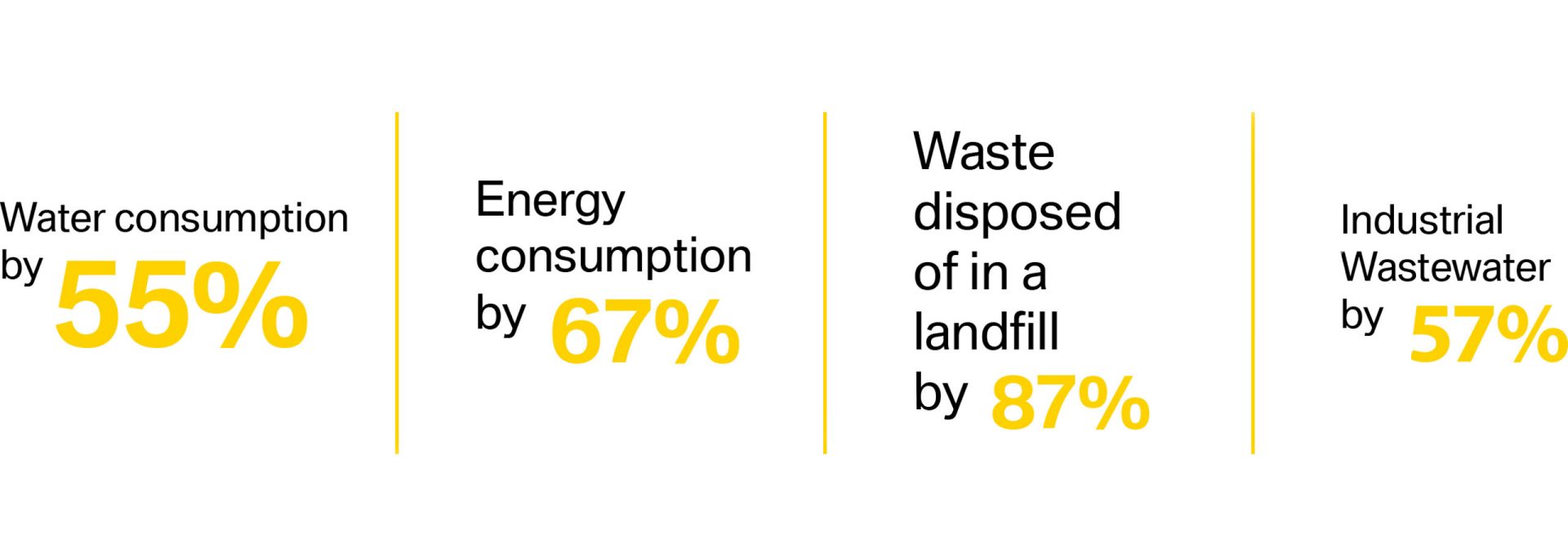

From 2006 to 2023, per vehicle shipped, BMW’s South Carolina plant has decreased: