RESOURCE-EFFICIENT PRODUCTION.

Sustainability plays an important role in every area of life. For this reason, we think, act and invest with the necessary vision today to ensure we can make a contribution.

ENERGY & EMISSIONS.

The BMW Group also cares about sustainable production, as well as quality. A wide range of major projects at the site are helping reduce energy consumption significantly – in fact, reductions of more than 35 percent have been achieved in this way in the last ten years alone:

- Switching to LED lighting in all production areas has also reduced energy consumption by more than one gigawatt hour per year.

- An energy-optimised operating concept was implemented in several areas of mechanical production. This is comparable to the auto start-stop feature in cars: The system automatically switches to stand-by if there are no parts awaiting processing.

- Standards at the Development site in Steyr are also geared towards the future, with higher performance, lower fuel consumption and reduced emissions.

Energy Efficiency in High-Pressure Pumps for Cooling Lubricant.

To optimize the energy of our production facilities, the machining centers in mechanical production were analyzed, with a focus on high-pressure cooling lubricant pumps. The installation of frequency converters achieved an energy optimization through speed-controlled operation. This measure saves up to 350 tons of CO2 annually.

WATER & WASTEWATER.

We pursue the goal of actively conserving resources and protecting the environment. One example is wastewater-free production at Plant Steyr: Thanks to an innovative combination of various membrane technologies, all production wastewater from the plant can be optimally processed and fed back into production. In this way, the plant conserves many litres of water per year and no production wastewater enters the public sewage system.

WASTE & RECYCLING.

We are economical in our use of materials and ensure that any resulting waste materials are re-used in a meaningful way. Our suppliers are also integrated into this environmental policy: To save packaging material, for example, products and materials are delivered and transported in mesh containers.

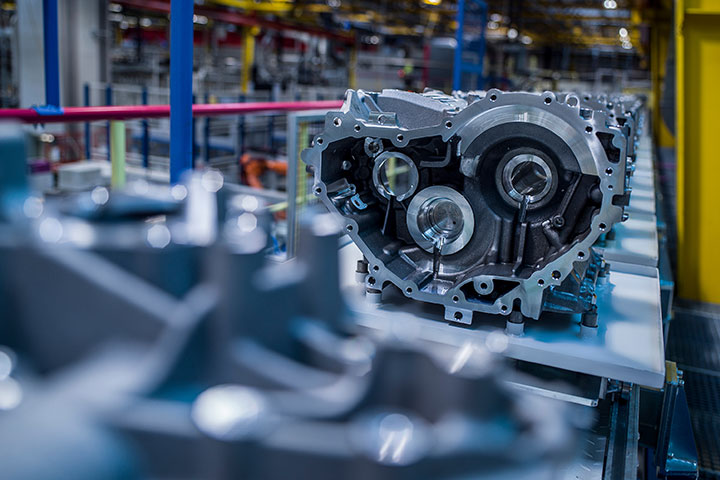

The aluminium chips generated during production of cylinder heads and crankcases provide a good example of how to manage resource cycles. Chips are collected according to type and processed to produce liquid aluminium. This is then further processed at the BMW foundry in Landshut to form new engine components.

NEW TRAFFIC CONCEPT.

WTo make the traffic situation as stress-free as possible for people in the region, we have developed a new traffic concept. First, employees at the plant were asked about their mobility patterns; then, we worked closely with the city of Steyr and its residents to put together a package of measures promising significant improvements.

Sustainability in various forms