From inception to production and recycling: the BMW Group replicates the entire high-voltage battery and battery cell value chain in-house – in its centres of excellence and with a holistic approach.

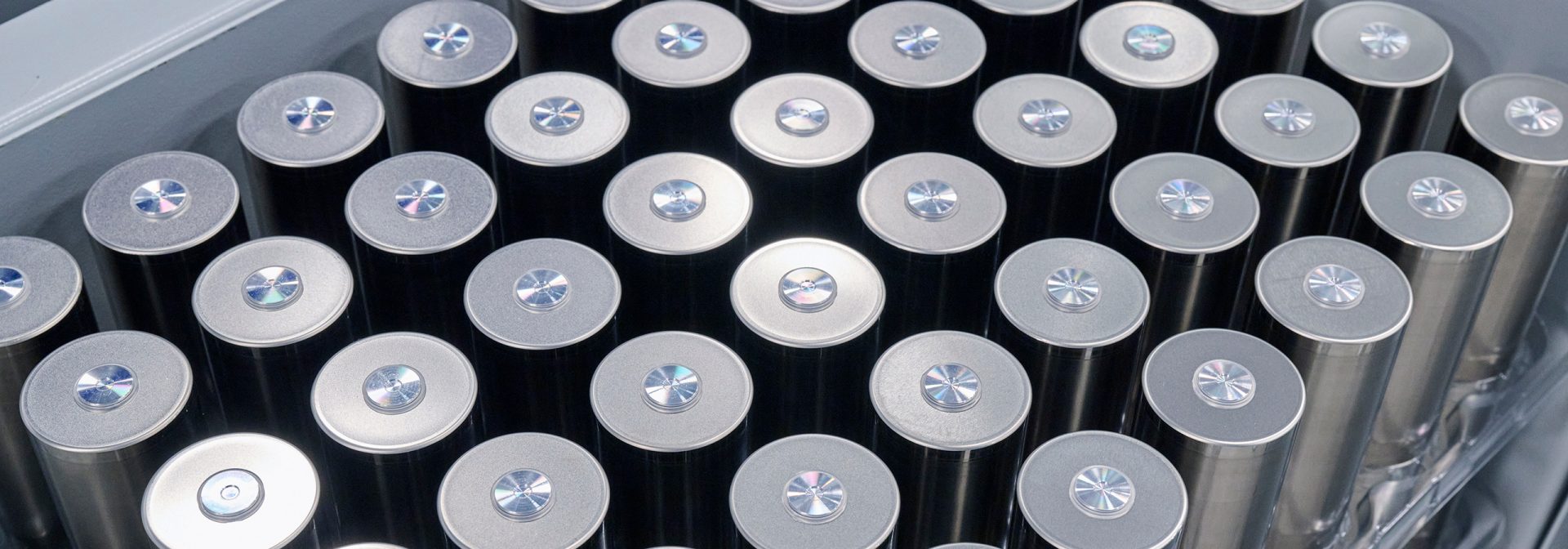

Our Battery Cell Competence Centre in Munich carries out research into new cell technologies – for which our excellence centre for battery production develops manufacturing methods. The focus of our experts is on producing top-quality battery cells with minimum resources.

And that’s not all: the BMW Group also operates a Centre of Excellence for Battery Cell Recycling, which uses an innovative direct recycling process to recover valuable raw materials from used batteries and return them to production. A major step towards a circular economy.

Battery cells are a key component of any high-voltage battery, but before they can enter large-scale production, the right production processes have to be engineered to make them, and pre-series batteries undergo rigorous testing. At the BMW Group, this is done at pilot plants in Munich itself and in nearby Parsdorf and Hallbergmoos.

Find out more about these key locations here.