Every BMW is fitted with a piece of pure innovative power made in Landshut – and it’s been that way for the past half century: On 2 January 1967, Bayerische Motoren Werke acquired the medium-sized carmaker Hans Glas GmbH based in Dingolfing. At the time, about 140 people worked at the company’s Landshut site for vehicle components. In 1969, the local newspaper, Landshuter Zeitung, ran the headline: “A present for Pentecost: BMW about to build cars in Landshut”. It marked the beginning of a real success story.

Sustainable Mobility of Tomorrow.

With the power of the desert sun: Since the beginning of 2021, the light metal foundry has been sourcing aluminium for the production of which electricity from solar energy is used. This marks an important milestone on the road to the company's goal of lowering CO2 emissions in its supplier network by 20% by 2030. Since producing aluminium is highly energy-intensive, the use of green power - such as solar electricity - has significant potential for reducing CO2 emissions. With 43,000 tonnes valued in the three-digit million euros, the purchase of solar aluminium covers almost half of the annual demand of the light metal foundry at Plant Landshut.

The power of innovation from Lower Bavaria: BMW Group Plant Landshut in Lower Bavaria once again played its role as an innovation driver for the future of the automotive industry. It supplies key high-tech components that give a face to the BMW iX set to roll off the production line in Dingolfing from 2021. The BMW iX is the BMW Group's first fully-electric production vehicle to be pre-configured for highly automated driving. On 22 July 2020, Dr. Andreas Wendt (member of the Board of Management of BMW AG, Purchasing and Supplier Network) and Hubert Aiwanger (Deputy Minister-President of Bavaria and the state’s Minister for Economic Affairs, Regional Development and Energy), inaugurated a new production hall at the Landshut location that will manufacture the innovative kidney grille – the “eye” – for the BMW iNEXT.

Continuous Growth.

In December 2019, the light metal foundry at BMW Group Plant Landshut was certified for its sustainable use of aluminium. It meets the standards of the Aluminium Stewardship Initiative (ASI), an international organisation supported by environmental and industrial associations, aluminium producers and processing companies. The ASI has defined sustainability criteria for an environmentally and socially responsible aluminium value chain. Through this initiative, following an audit by an independent third party, the BMW Group received confirmation that its light metal foundry handles aluminium in a conscious and responsible manner.

Sustainable by design: On 26 July 2018, the plant's new and highly efficient co-generation plant went on-stream. It was designed to produce about 50 percent of the plant’s annual electricity requirements and reduce CO2 emissions by 40,000 tonnes a year, compared to conventional technology. Co-generation plants, also referred to as CHP plants, are energy systems that convert gas into electricity and immediately utilise the resulting heat. Since less waste heat is lost than in conventional electricity generation, up to 90% primary energy use is possible.

On 22 September 2017, Ilse Aigner (Deputy Minister-President of Bavaria and the state’s Minister for Economic Affairs) and Markus Duesmann (member of the Board of Management of BMW AG, Purchasing and Supplier Network), inaugurated a new supply centre in the presence of representatives from the political sector, business and the community. Through the approx. 48,000 m² complex, technologies at the innovation hub in Lower Bavaria are supplied with materials in a highly efficient and flexible manner. Components produced in Landshut are shipped to BMW Group vehicle and engine plants around the world.

The foundation stone of a new supply centre was laid on 6 July 2016. On 27 October 2016, under the motto “ready for the innovations of tomorrow”, Alexander Dobrindt (German Federal Minister for Transport and Digital Infrastructure), Oliver Zipse (member of the Board of Management of BMW AG, Production), together with representatives from the political sector, business and the community gave the starting signal for the BMW Group's new centre for lightweight construction at its Landshut location. The site conducts cross-technology research into high-tech materials for future mobility.

The BMW Group opens a new chapter in Landshut: The Bavarian Secretary of Economic Affairs, Ilse Aigner, and BMW AG’s Head of Production, Oliver Zipse, celebrate with representatives from politics, business and society the symbolic laying of the foundation stone for the company’s new Lightweight Design and Engineering Center.

The site received a new showpiece: the Visitors Center, which opens in October. This is where today guests from all over the world are welcomed. Other pioneering decisions taken for the site include the setup of the BMW Group’s new Lightweight Design and Engineering Center in Landshut as well as the northeast expansion of the plant by a supply center.

Strictly on course for the future: The light metal foundry invests 100 million euros in expanding production.

The carbon production area for the BMW i models is commissioned in March. The production area Plastics Exterior is recognized as the “Best Factory 2012”.

The foundation stone is laid for the new smelting plant in Landshut. The site receives the Automotive Lean Production Award.

The Landshut foundry is the first of its kind worldwide to introduce odor-free production.

Dawn of a new era.

The light metal foundry celebrates its 20th anniversary at the Landshut site. Despite times of economic volatility, BMW invests approx. 70 million euros in BMW Group Plant Landshut.

A new production facility is built for the Technology Interior.

The vocational training and development center is inaugurated in July. BMW Group Plant Landshut celebrates its 40th anniversary.

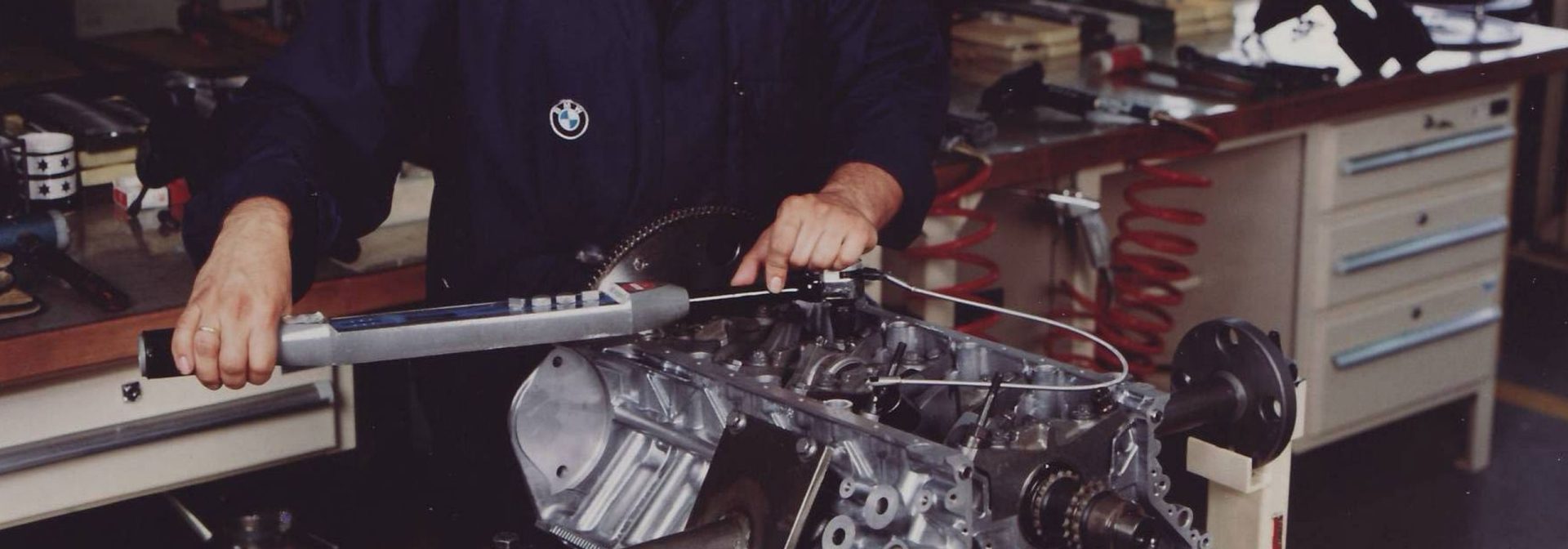

The exchange engine production is expanded in April. A new vocational training and development center is built, prompting Landshuter Zeitung to run the headline “Hooray for the workforce”. After all, skilled employees are vital for the company’s future success.

A new model and prototyping unit for the interior is inaugurated in October. BMW Group Plant Landshut’s Technology Interior once again receives the SPE (Society of Plastic Engineering) Award.

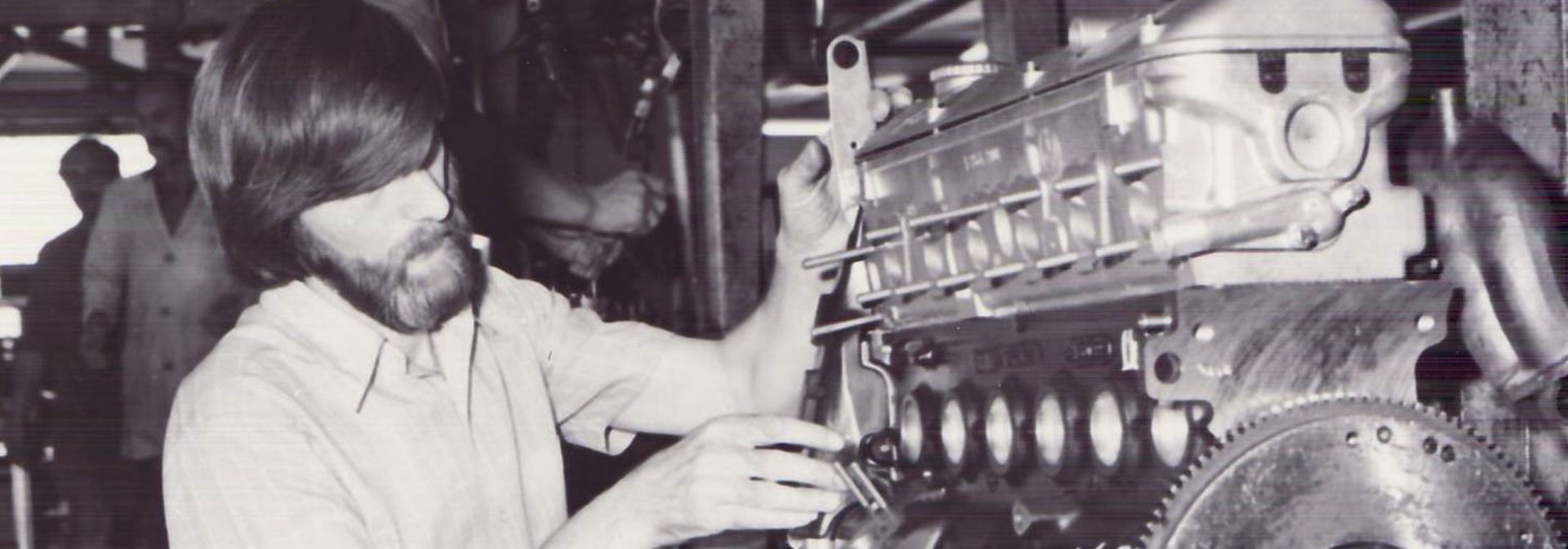

Production starts both at the new light metal foundry and the magnesium foundry. The headline in the regional business publication Niederbayerische Wirtschaft: “Lower Bavaria writes technological world history”.

The groundbreaking ceremony for the new exchange engine production is celebrated in May. A nice gesture: Formula 1 race driver Ralf Schumacher visits the plant in December to sell mulled wine to the workforce in support of the charity organization “Haus International”.

Production reaches a daily output of about 900 dashboards, 2,900 bumpers, 4,500 cylinder heads, 3,300 crankcases and 4,100 driveshafts. In addition, 14,000 exchange engines and 38,000 tons of cast components are made annually.

Construction for the expansion of the light metal foundry begins. The exchange engine production celebrates its 30th anniversary. “A second life for scrap metal” reads a headline in Landshuter Zeitung in January. Over 500,000 exchange engines have been produced since 1971.

In May, representatives of BMW Group Plant Landshut sign an agreement on an endowed BMW professorship with Landshut’s University of Applied Sciences (automotive lightweight construction).

Investing in the third millenium.

December sees the commissioning of the Landshut Innovation and Technology Center (LITZ). The plant receives the Bavarian Quality Award in the category Car Body Equipment. The light metal foundry celebrates its tenth anniversary at the Landshut site.

Construction of the lightweight construction center begins in September. The 500,000th engine leaves the exchange engine production.

BMW Group Plant Landshut celebrates its 30th anniversary with a team of approx. 3,150 employees.

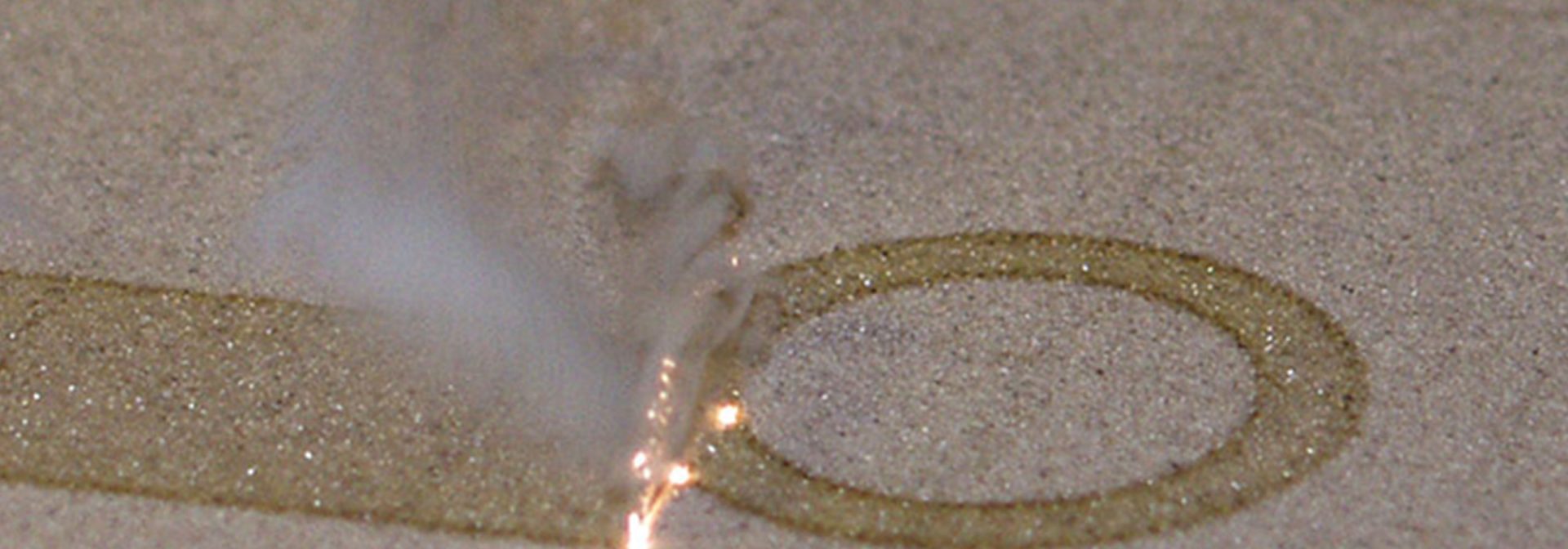

“Quality takes top priority”, reads a headline in Landshuter Zeitung in September. BMW is the first company to be granted the certificate QS 9000 by the German Technical Inspection Agency. The site in Landshut develops new and improved procedures, such as laser-sintering in the foundry. The exchange engine production celebrates its 25th anniversary with now 200 employees.

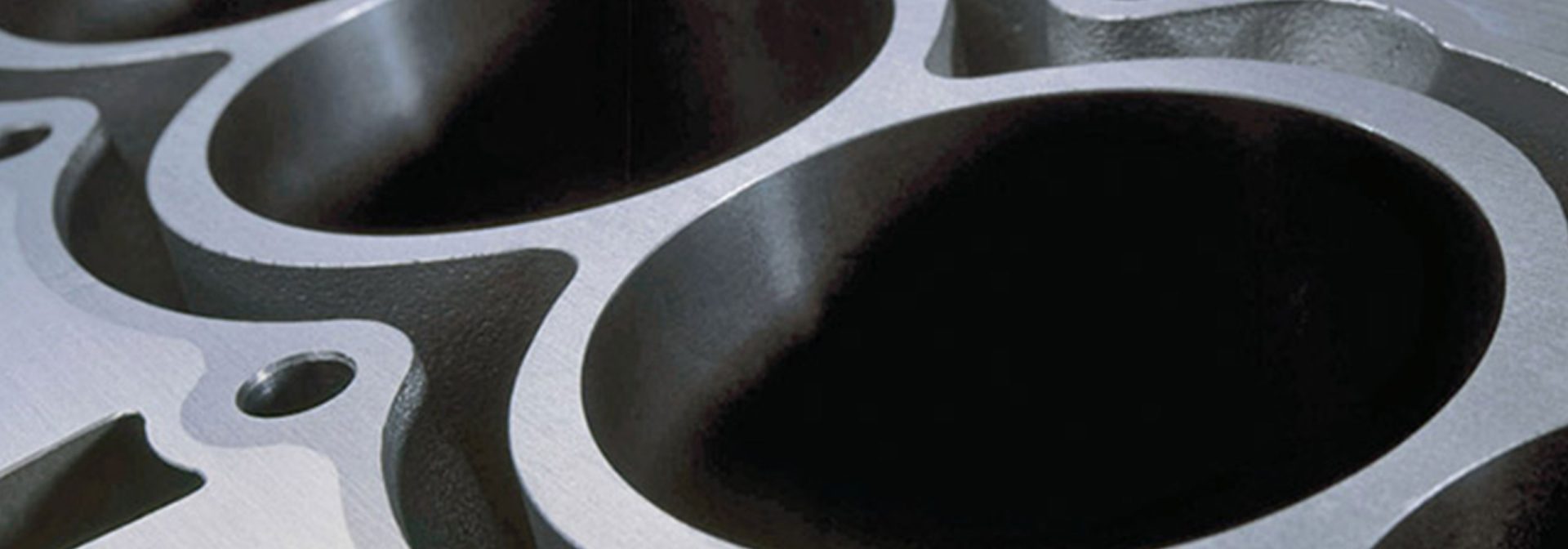

The foundry is cleared for the introduction of the lost-foam casting method. BMW Group Plant Landshut receives the Innovation Award of the Society of Plastic Engineers International for the world’s first dashboard made of a single material.

“500 new jobs created at BMW”, reads a July headline in Landshuter Zeitung. A dashboard can now be made in less than ten minutes.

Landshut produces its five-millionth dashboard.

BMW Group Plant Landshut receives the SPE (Society of Plastics Engineers) Grand Award in the category Plastics in recognition of a plastic suction unit.

The exchange engine production celebrates its 20th anniversary.

June marks the launch of the pilot project on full car recycling. The headcount exceeds the next magic mark, now standing at 3,040 in total.

Development and expansion.

Good luck! On 21 January 1989, the first cast part is made in Landshut. The technical center for plastics is moved from Munich to Landshut.

The headcount at BMW Group Plant Landshut increases to 2,000. Twenty apprentices can choose between ten skilled professions at the new training workshop. In July, the plant signs a cooperation agreement with Landshut’s University of Applied Sciences.

Construction of the new foundry begins in March. BMW Group Plant Landshut now has about 1,600 employees. The site celebrates its 20th anniversary.

“BMW invests in 1,000 new jobs”, Landshuter Zeitung announces in March. As early as February, construction for a new building east of highway B299 in Ergolding begins. The fettling shop is put into operation in August, and the exchange engine production celebrates its 300,000 engine.

The decision to build a new foundry in Ergolding is taken in June. Total investment stands at approx. 200 million marks; another 800 members of staff are recruited.

The production of exchange engines increases to a daily output of 130 engines, 35 rear-axle transmissions and 500 other engine parts for a total of about 115 engine types. Landshuter Zeitung reports about “Millions in investments – also for better workstations”.

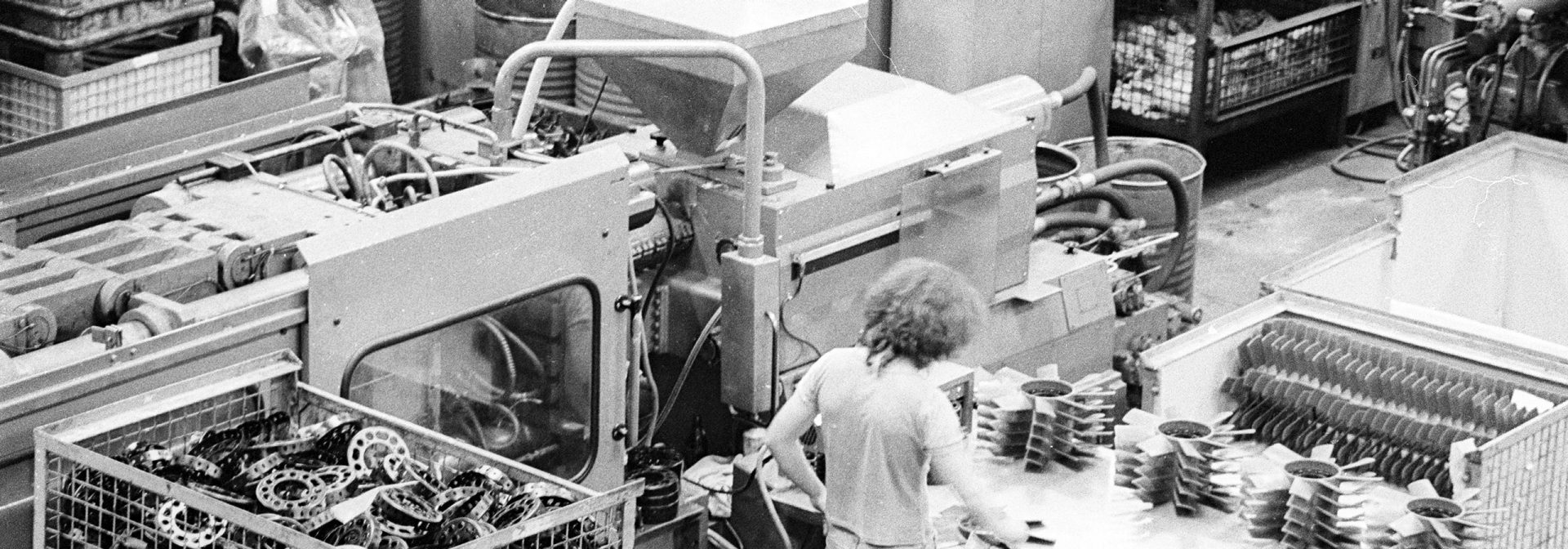

The plastic production for the interior makes about 38 million molded parts annually, or 126,666 components a day.

In the exterior unit, a new paint spray facility for up to 100,000 molded parts daily is commissioned. The headcount at BMW Group Plant Landshut now stands at about 1,100 people. As a measure to solve logistics problems, a “super canopy” is being built, Bayernmotor reports in November 1982.

The first materials testing lab is established at BMW Group Plant Landshut. The exchange engine production celebrates its tenth anniversary.

The steering shaft facility is relocated from Landshut to Berlin. Construction of a powerhouse and a fire station begins. In total, “BMW is investing another 30 million marks in Landshut", Landshuter Zeitung titles on 26 April 1980.

The decade of consolidation.

The production of exchange engines reaches a daily output of 100 engines, 70 rear-axle transmissions and over 530 small parts. The plastics unit produces 89,000 individual parts a day. In April, BMW Group Plant Landshut hires its 1,000th member of staff.

A new hall for the driveshaft production is built. Starting in September 1978, the first apprentices join the team of BMW Group Plant Landshut, which is “to grow by 50 percent”, as a June headline in Landshuter Zeitung declares.

The BMW Group’s site in Landshut celebrates its tenth anniversary, “looking back on a year 1977, which wasn’t always easy but turned out very successful in the end”, as Landshuter Zeitung puts it.

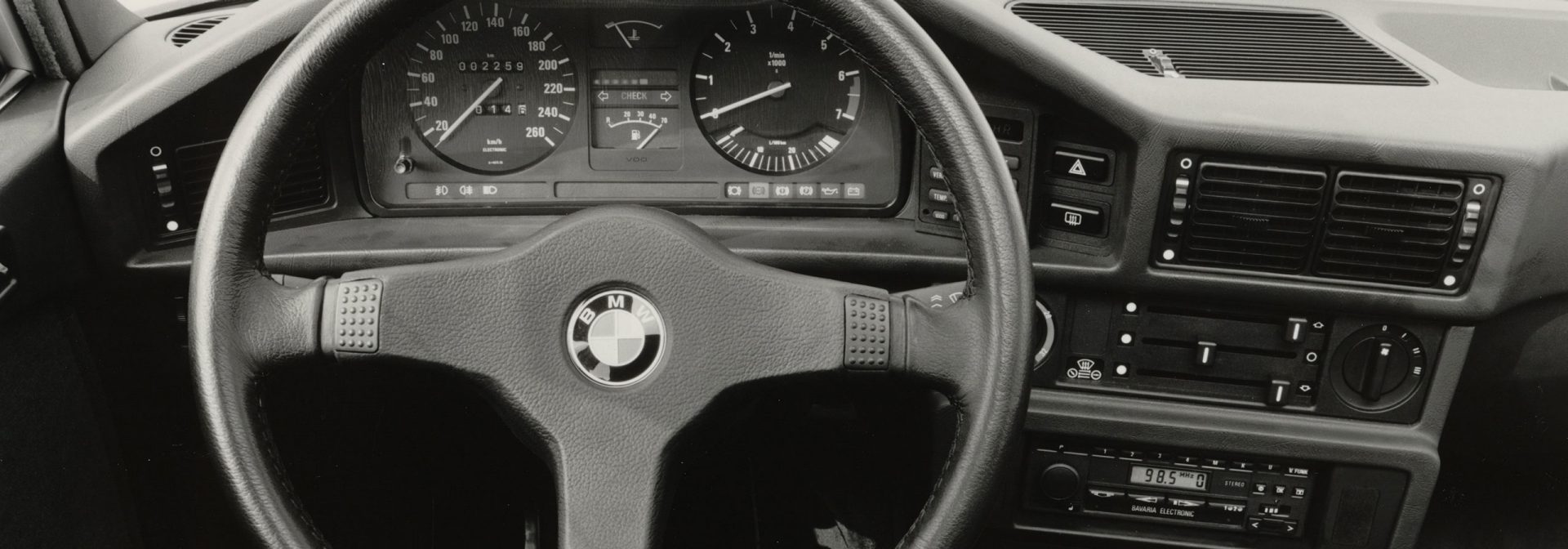

In the plastics production unit for interior components, a dashboard is made in only 30 minutes. The headcount at BMW Group Plant Landshut has risen to about 800.

The Landshut site employs more than 600 people.

With the relocation of the plastics production unit to BMW Group Plant Landshut, “the situation in the Munich-based foundry has improved as well”, according to bm-bayernmotor, the BMW Group’s staff magazine at the time. However, initial ideas to relocate the foundry as well are being considered.

Plastics production is moved from Munich to Landshut where the production of the first dashboards begins.

In Lower Bavaria, site Dingolfing is the main object of investment for the BMW Group. For the time being, BMW Group Plant Landshut, which has a workforce of 600 people at this point, is not expanded.

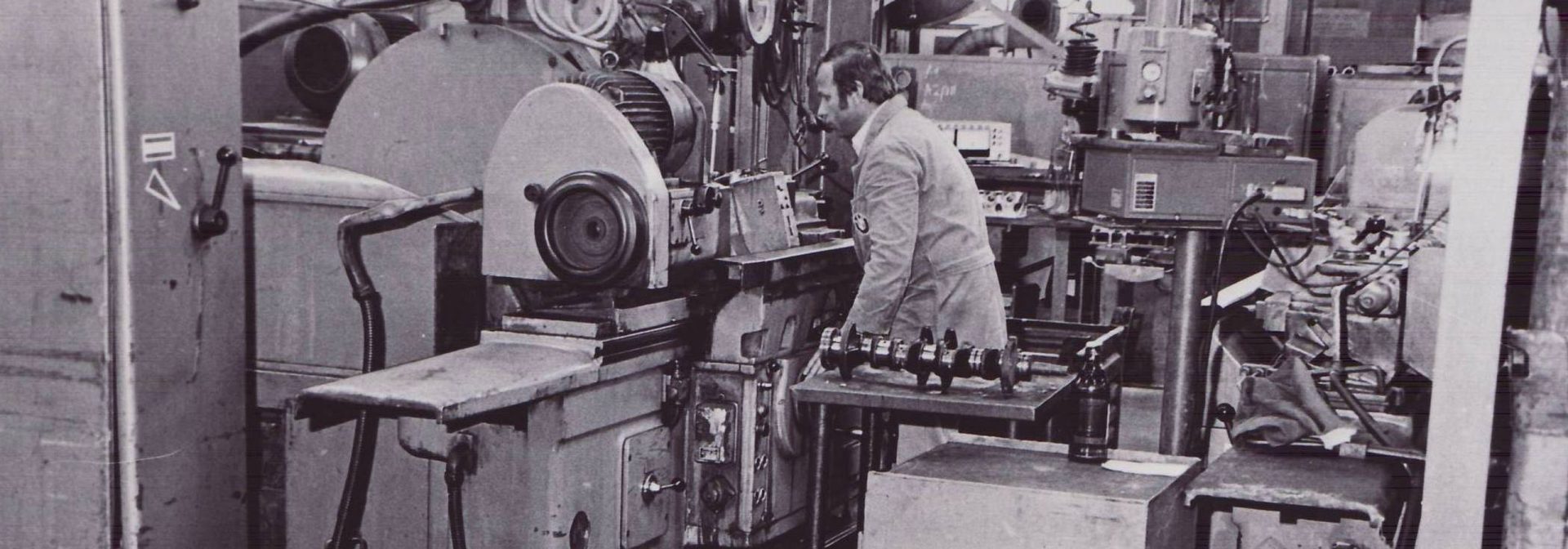

The exchange engine production moves from Dingolfing to Landshut. The facility manufactures 6,572 units of 25 different drive variants per year.

Following a trade-off with another company, Emslander, and the subsequent transfer of their buildings and acquisition of additional halls, BMW moves from its site on Siemensstraße/Ottostraße to its new premises west of highway B299.

From Hans Glas to BMW.

“A present for Pentecost: BMW about to build cars in Landshut” is the headline of the local newspaper, Landshuter Zeitung, on 24 May 1969. Planning anticipates a workforce of between 2,000 and 3,000 people.

About 140 people work at BMW Group Plant Landshut.

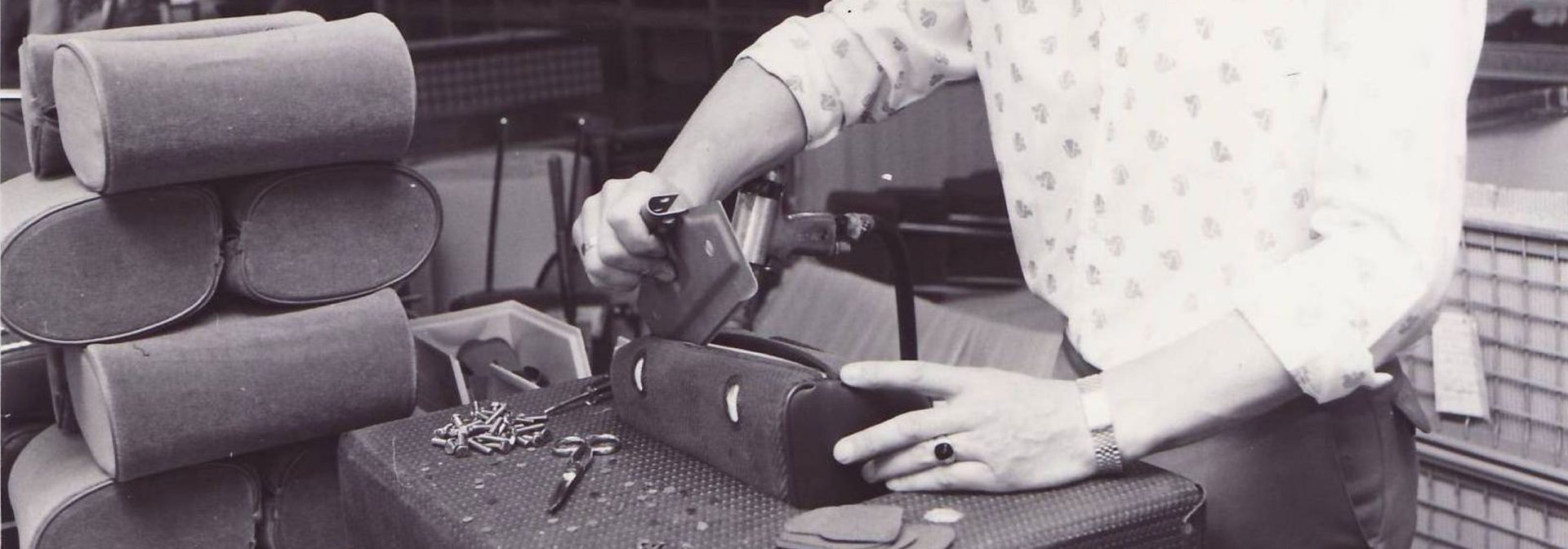

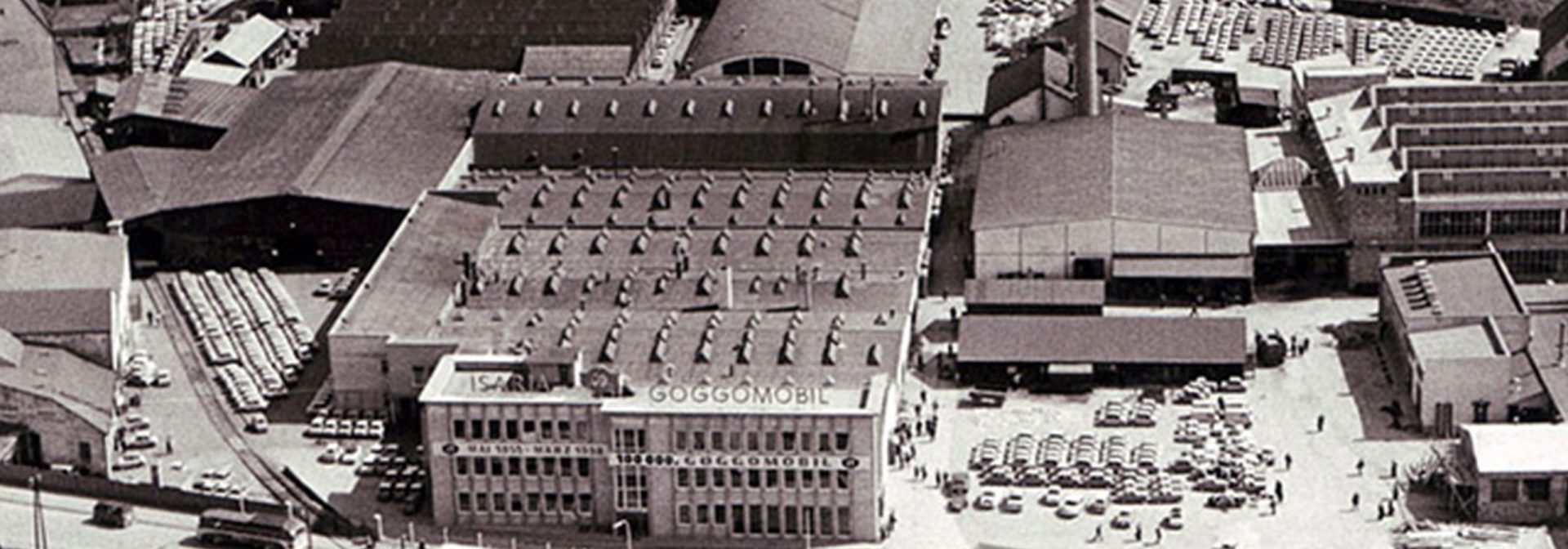

BMW AG in Munich acquires the medium-sized carmaker Hans Glas GmbH based in Dingolfing, producer of the Goggomobil.