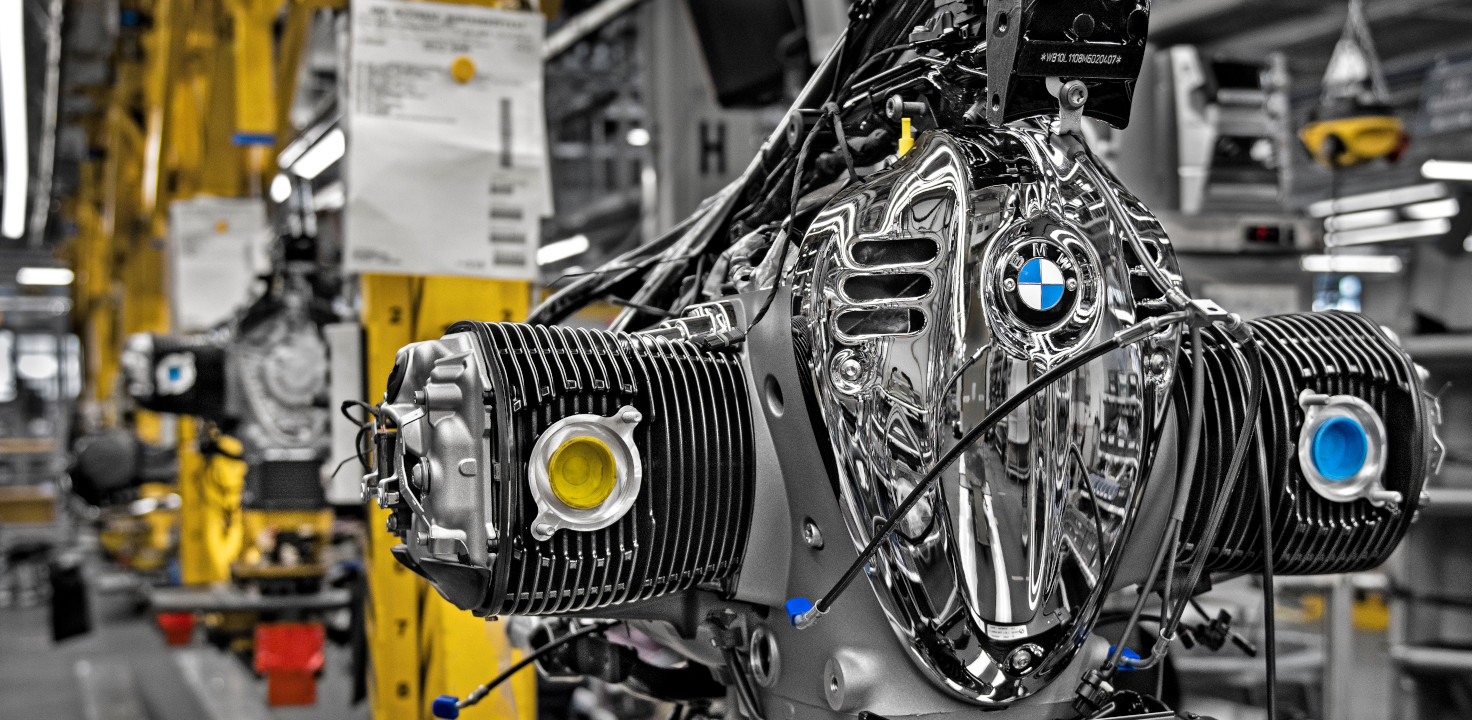

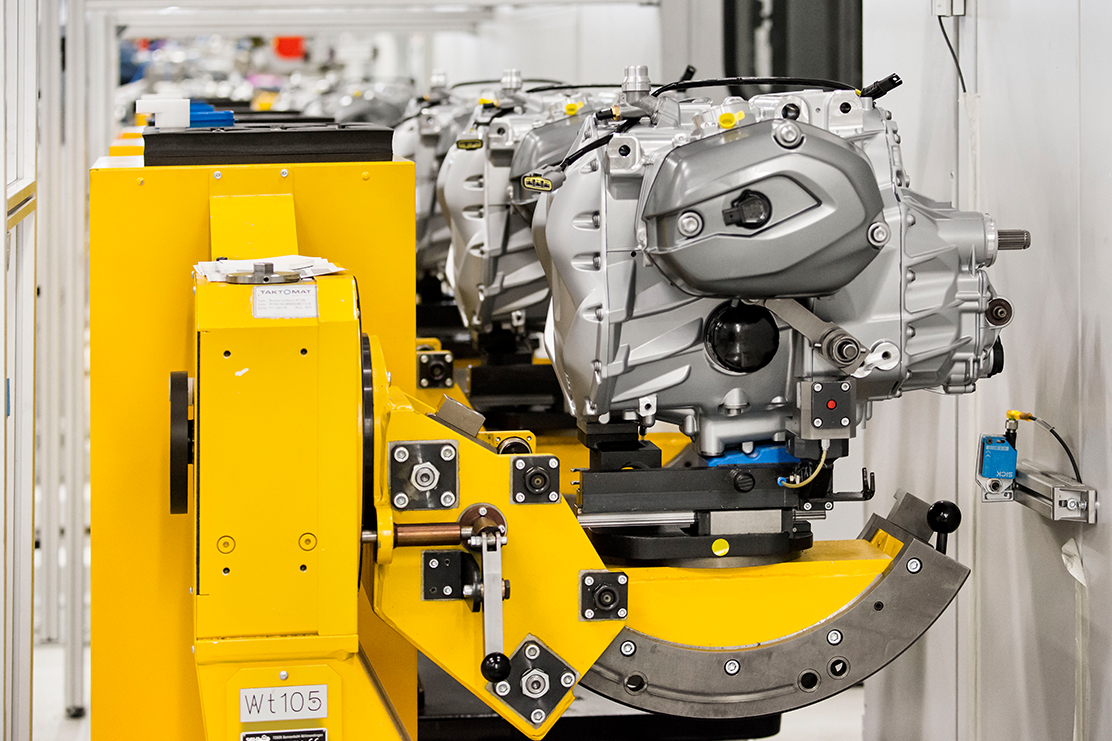

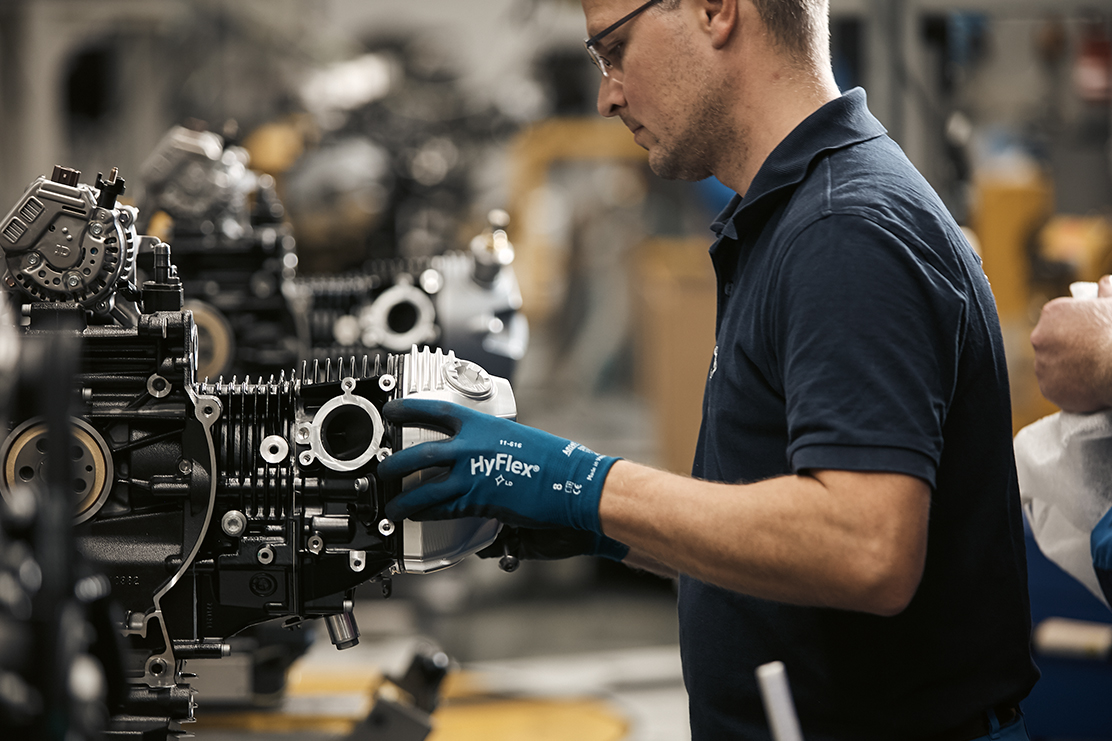

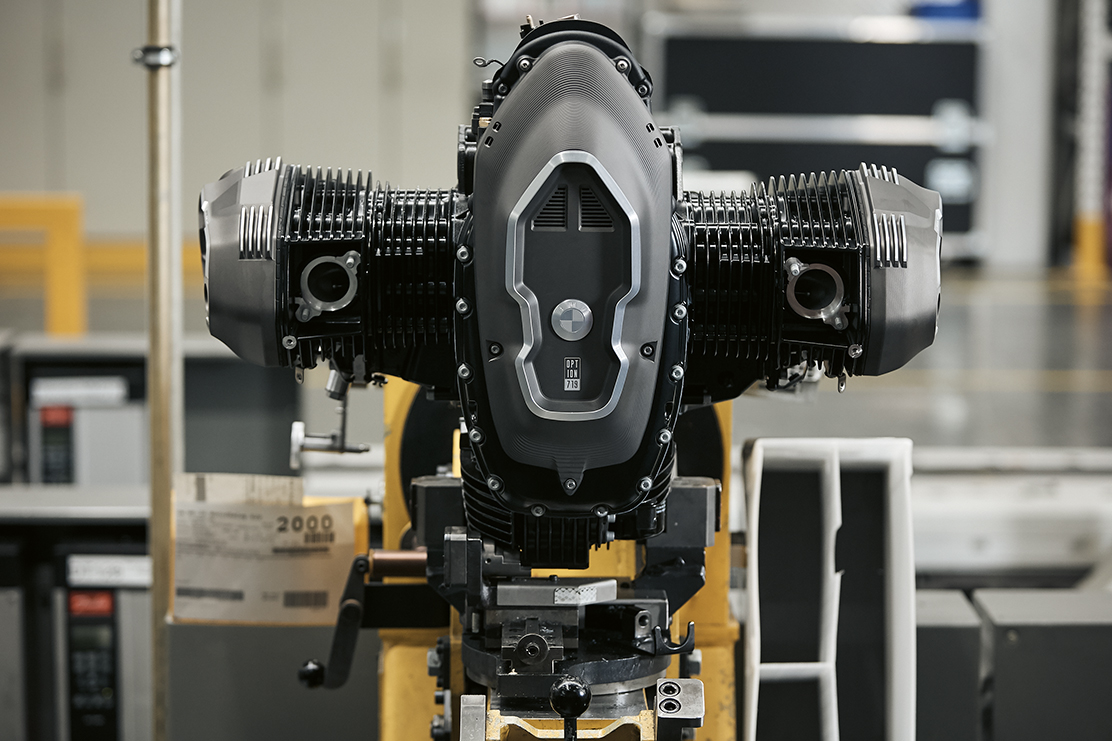

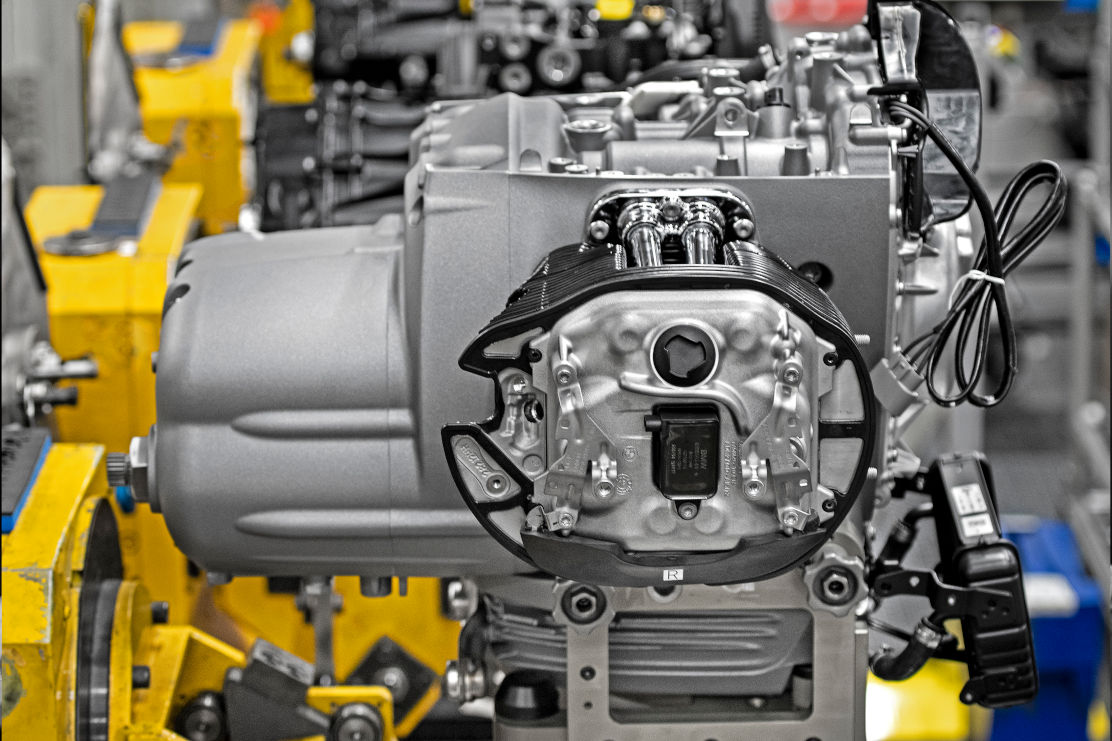

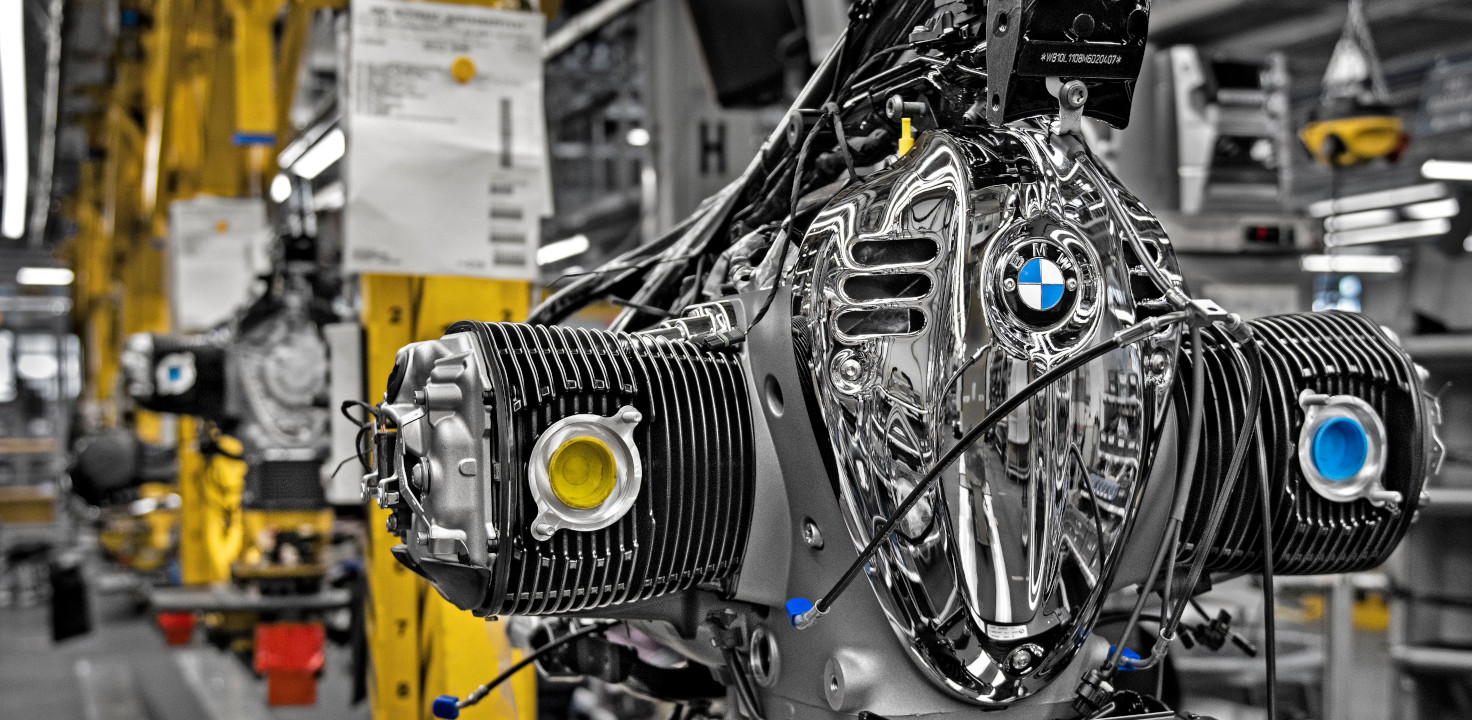

Around 200 engine specialists work in two shifts, building up to 600 high-performance engines a day from over 600 different small parts and components. Four assembly lines produce the boxer engines (air-oil and air-water cooled) as well as the in-line four-cylinder and six-cylinder engines. It takes around 90 minutes to assemble a boxer engine and around 250 minutes to assemble an in-line six-cylinder engine.

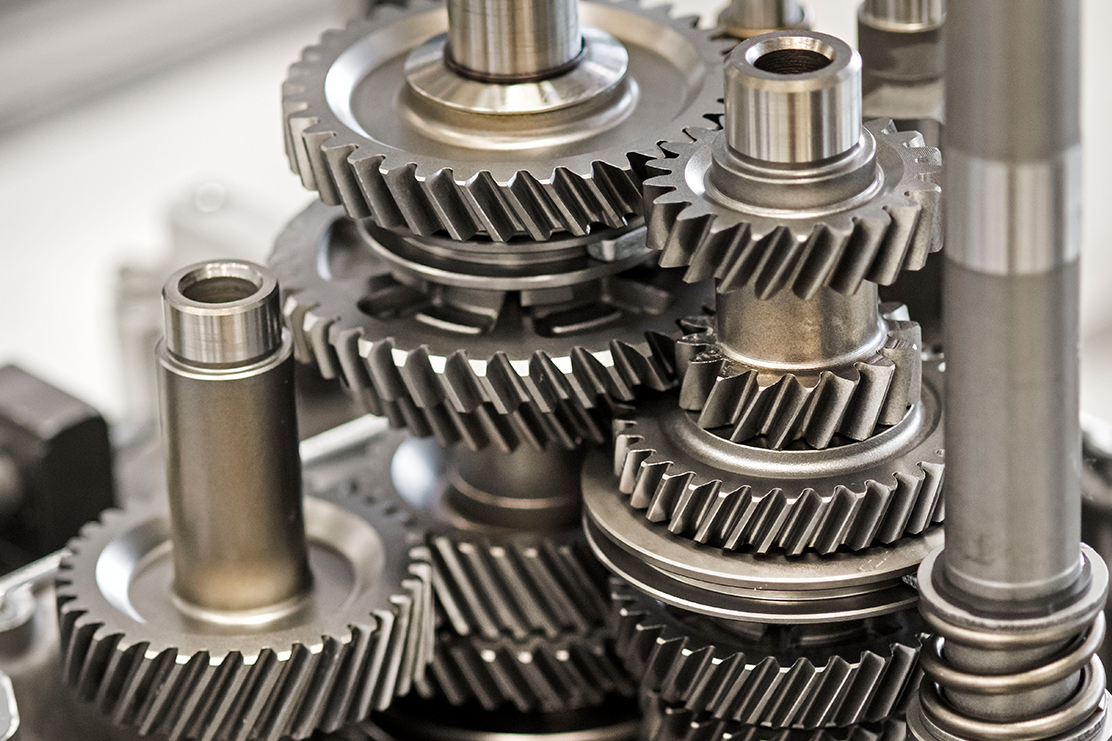

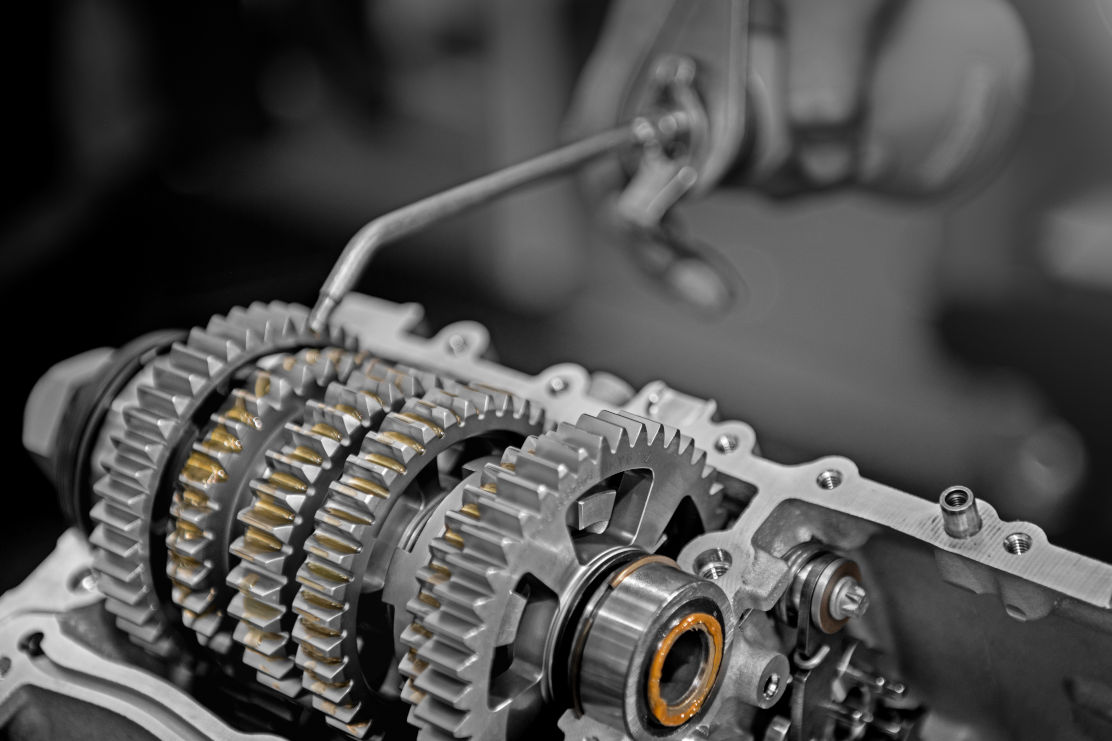

To ensure premium delivery quality, each engine is subjected to a combined cold and transmission test. Torque, speed, noise emission and various pressure tests are carried out on the running engine. Every engine also undergoes a leak test to prevent any possibility of fluid leakage. Nothing is left to chance.

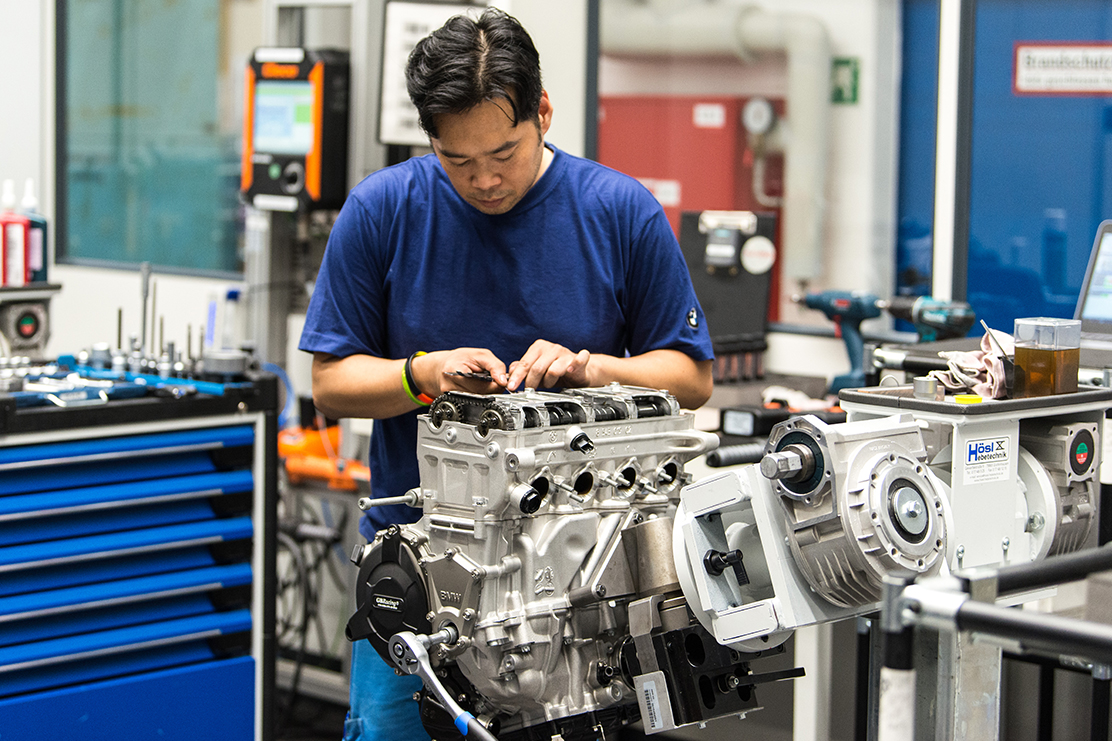

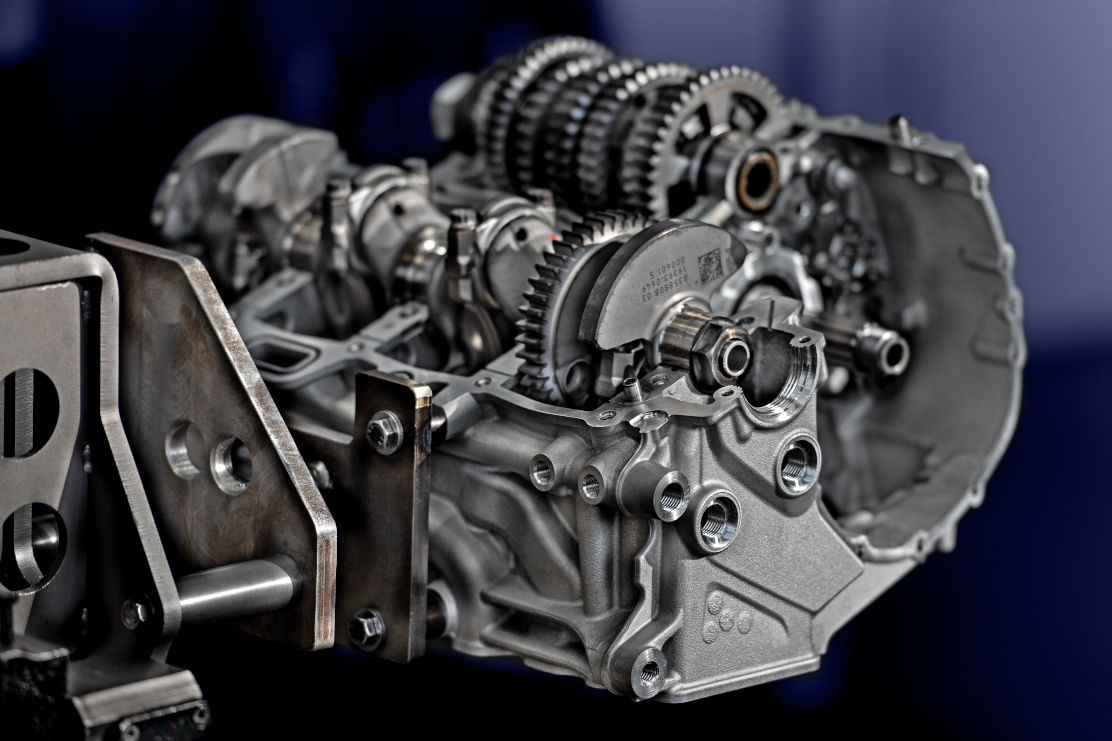

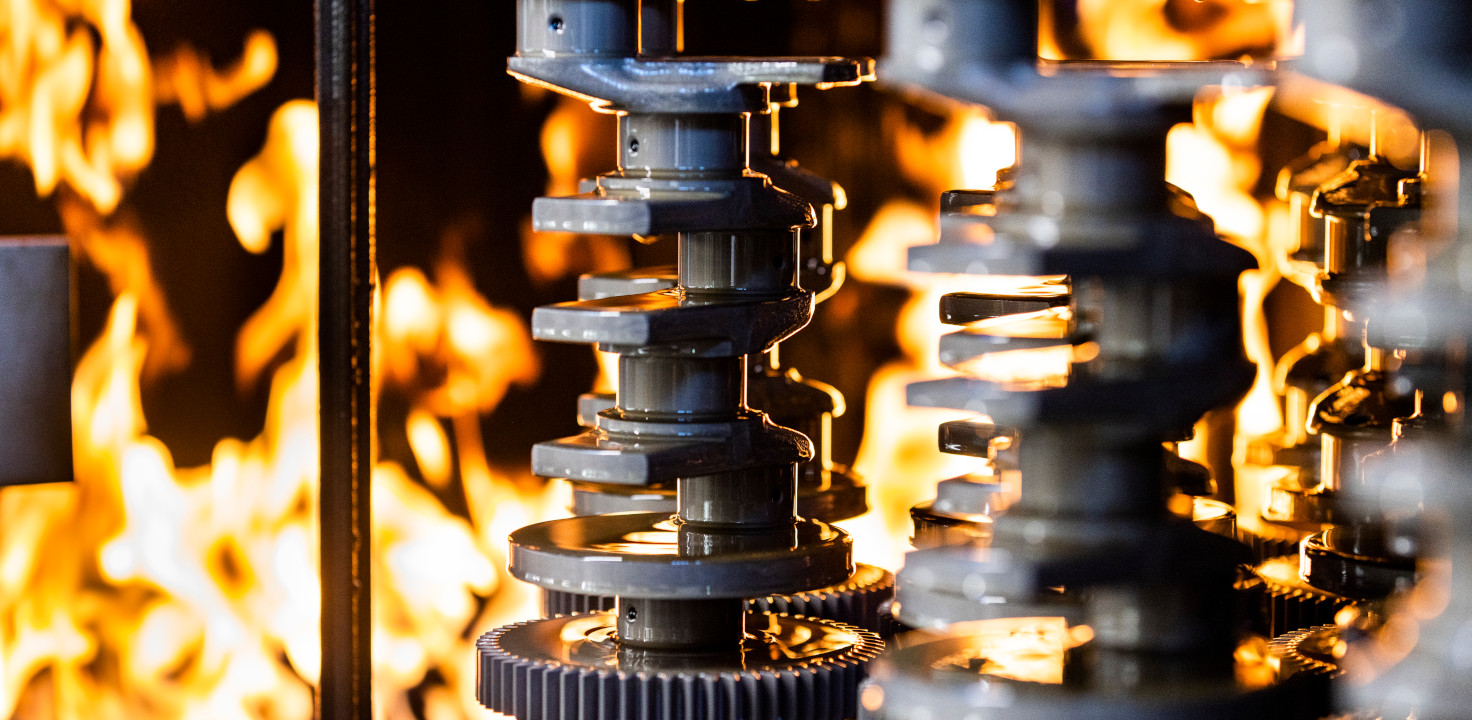

Besides the traditional series production, a small team works on exclusive racing engines. These have to meet the highest demands and withstand enormous strains, for instance in 24-hour races. Our racing engines are assembled manually in a special workshop and undergo precise analyses after their use on the track. Our series production engines benefit from the expertise gained by analyzing such extreme racing conditions.