Assembly takes hundreds of individual parts and creates BMW and MINI high-performance engines to customer specifications. State-of-the-art production technologies are perfectly complemented by the skills and know-how of qualified assembly workers.

SETTING THE PACE.

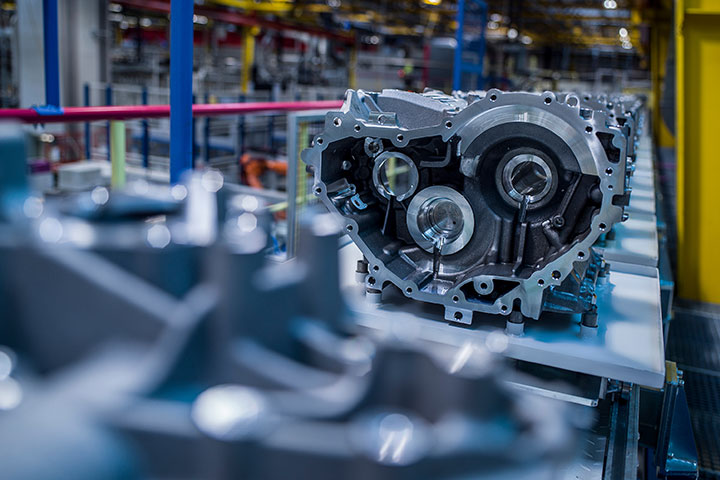

Engine assembly.

Countless engine variants.

It all begins with putting the basic engine together. The core parts are assembled along with other components to create the engine block. The engine is then completed step by step. With hundreds of different engine variants passing through our assembly lines, things can get interesting. But since all our employees are experts in their field, they master the high level of complexity with ease – supported by state-of-the-art production processes with a high degree of digitalisation, the very latest logistics and an innovative modular system with engine sets for engine assembly.

Environmentally-friendly cold testing.

Every finished engine undergoes a final computer-aided functional test known as a “cold test”. This procedure is particularly environmentally-friendly, since the engine is powered by an electric engine without using any fuel. Afterwards, the engines are sent to the vehicle plants for the so-called “marriage”, where engine, chassis and body are united.

Driving a revolution: modular engines.

Based on a standardised in-line design principle, a single assembly line will be able to produce up to four different basic engines in the future; these will then form the basis for performance and country-specific variants.

Ergonomic workplaces.

Electrically-adjustable overhead tracks along assembly lines allow employees of different heights to work as ergonomically as possible. This plays an important part in helping employees stay healthy and maintain their performance.